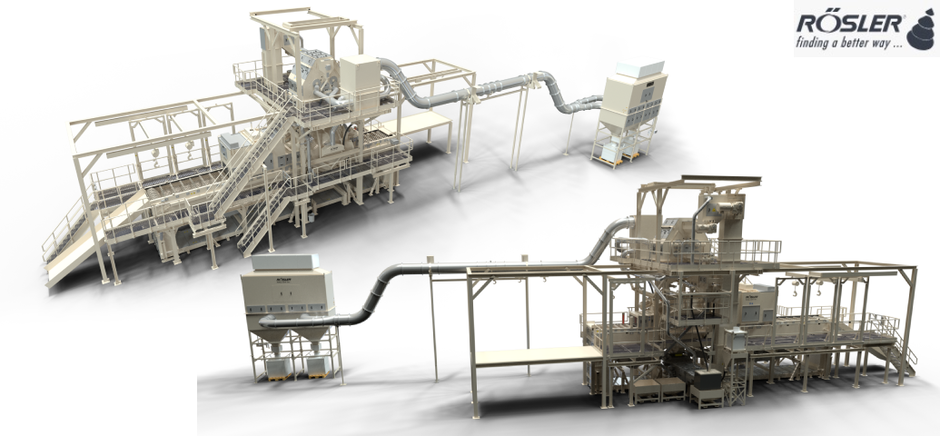

Funosa, a Spanish foundry with over a century of experience, is implementing a strategic modernization plan to enhance process efficiency, reduce environmental impact, and strengthen its commitment to customer quality expectations. A key part of this project has been the replacement of an old shot blast machine by a sturdy, ultra-modern and energy-efficient shot blast system from Rösler. The wire mesh belt continuous flow shot blast machine model RDGE 1250, was specifically designed for the de-sanding of heavy iron castings. Its main features are not only high productivity but also high wear-resistance. Moreover, this shot blast system also offers greatly improved safety and maintenance features. The new machine represents a significant step towards achieving improved sustainability at Funosa.

Funosa makes targeted investments

For over 100 years, Funosa has been a trusted supplier of ductile and grey iron castings, delivering mid- and large-scale batches to a diverse range of industrial sectors. The company combines deep technical expertise with a forward-looking approach to innovation and sustainability. For about 10 years the company has invested a sizable amount of capital and energy in modernizing its equipment and stream-lining its production. These investments are part of Funosa’s broader ESG-aligned roadmap, which focuses on energy efficiency, digitalization, and reducing the environmental footprint of foundry operations. For example, the company purchased a new core shooting machine that helped reduce the annual consumption of core sand by around 53 tons. The purchase of a new, extremely sturdy and energy-efficient shot blast system for de-sanding the castings is another highlight of the company’s modernization project. This investment, in the form of a Rösler wire mesh belt continuous flow shot blast machine, model RDGE 1250, offers another enormous cost-saving potential. Antonio Ortega, technical manager at Funosa, explains: „For us the new blast machine is another important step to make us fit for the future. The Rösler system is replacing an old, obsolete blast machine and will be substantially more productive, less noisy and much safer.“

Blasting of very heavy cast iron parts

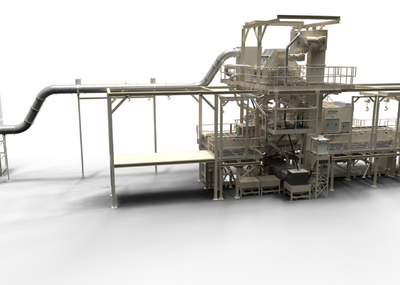

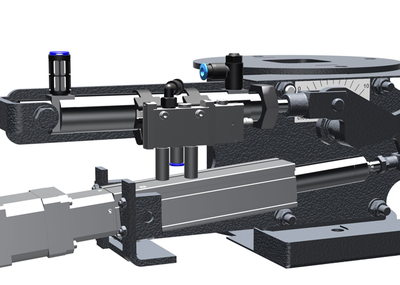

The new Rösler machine will predominantly be used for blast-cleaning flat but very heavy iron castings, for example, components for all kinds of machinery or truck control arms with weights of up to 150 kg. This application demanded a reinforced transport belt engineered to maintain structural integrity throughout the blasting process, ensuring optimal impact angles and continuous operation without slippage. At the same time, the belt loaded with the heavy castings must easily glide around the deflector pulley. The special design of the perforated pulley and a pneumatic version of the automatic belt tensioning device ensure that the belt is transporting the work pieces through the blast machine without any slippage. The work pieces are passing through the blast chamber at a speed of six meters/min. Eight Rösler EVO-42 turbines - four positioned above and four below the belt - project blast media with precision, using hardened tool steel blades to ensure thorough surface cleaning of the castings. The turbines have a total power of 340 kW and are equipped with a vibration control device.

To withstand the extreme working conditions in a foundry environment and to guarantee a long up-time, the design of the RDGE blast machine for Funosa is particularly sturdy and wear-resistant. For example, the blast chamber is made from 8 mm thick manganese steel, and the entire blast zone is lined with 15 mm thick, overlapping and replaceable wear plates, also made from manganese steel. The “hot spot” zone is additionally protected with 20 mm thick liners made from tool steel.

The global sales expert at Rösler, Norman Peter, explains: „This blast system for Funosa is not only an extremely productive and sturdy solution for de-sanding of large, heavy iron castings, but it also offers a high degree of safety and can be easily maintained. To maintain productivity, minimizing downtime during turbine maintenance is essential. This is supported by auxiliary tools such as an overhead crane trolley that enables quick and safe turbine replacement, each weighing nearly 300 kg. Therefore, minimal maintenance times are essential. These are achieved by clever auxiliary equipment such as a crane trolley on trusses that allows quick exchange of the turbines with a weight of nearly 300 kg.” Technical accessories like large maintenance platforms equipped with staircases instead of simple, hazardous ladders, an electrical safety contact strip to ensure the safety of manual removal of the castings from the transport belt, or a pallet storage section with safety sensors are additional features that make the work around the shot blast machine safe and easy.

Antonio Ortega from Funosa concludes: „The Rösler system fits perfectly into our equipment concept at Funosa. We are enthusiastic about the superb surface finish we achieved during the processing trials and the commissioning of our machine at Rösler. And we look forward to the first in-house tests after the machine starts operating at our foundry. Our cooperation with Rösler will not only help us to improve our manufacturing process and make it more sustainable. But it will also enhance our leading position in the market regarding innovation and operational excellence.”