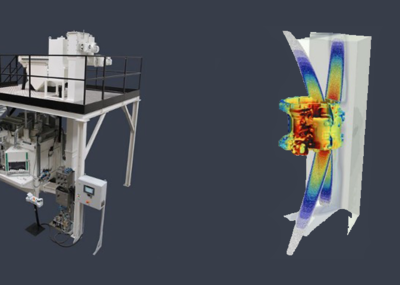

With the PowerLine Valve, Rösler simplifies turbine blasting. The newly developed shell valve ensures that the blasting performance is automatically optimised for different blasting requirements. The control is independent of the turbine speed and does not require time-consuming manual adjustment of the blast media quantity. This largely eliminates malfunctions and operating errors and increases process and machine safety. Process optimisation, abrasive consumption and energy savings thus lead to a high level of efficiency in the blasting process.

The turbines are the heart of a blasting system and have a significant influence on the blasting performance, the duration of a blasting process and its costs. In order to ensure optimum operation for different blasting requirements, time-consuming adjustments to the blasting media quantity are required during commissioning, the creation of a component-specific blasting programme, a blasting media change and turbine maintenance. A key parameter here is the speed of the turbine: If this is reduced - for whatever reason - this has an impact on power consumption and abrasive throughput. Rösler's new, intelligent scallop valve ensures that the blasting performance is always optimised and regulated automatically, regardless of the turbine speed. The sometimes manual, error-prone adjustment of the clam-shell valve using pushbuttons is now a thing of the past.

AI enables first self-learning abrasive regulation

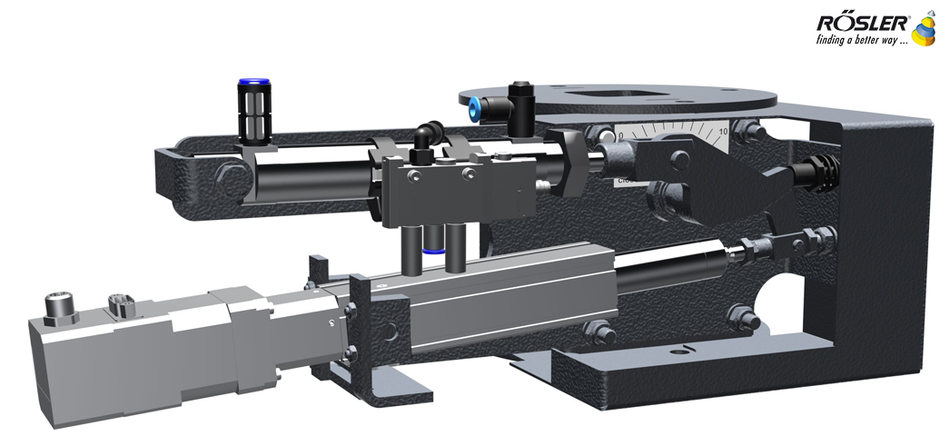

The basis for this new solution, for which a patent application has been filed, is a shell valve that is automatically positioned via sensors according to the specified amount of blasting agent. A routine was developed and programmed for the position calculation based on the parameters of power consumption, discharge speed and abrasive quantity. The software enables a separate control diagram to be created automatically for each turbine within a few minutes via the menu item "Teach in blast media quantity", for example. No manual intervention is required. The optimum process parameters for the respective blasting process, such as discharge speed, blast media quantity or power consumption, can then be entered simply and intuitively by employees via the control panel. This makes it possible, for example, to work with a higher blasting agent quantity and discharge speed if a high throughput is required. It is also possible to blast sensitive workpieces with the lowest possible amount of abrasive and blasting speed for processing in line with requirements.

More energy-efficient, safer and faster blasting processes

In daily operation, the new Rösler PowerLine Valve ensures significantly faster blasting processes. The previously tedious manual adjustment of the shell valve is no longer necessary. Malfunctions and operating errors are largely eliminated and blasting processes run reliably and reproducibly, avoiding unplanned system downtimes. At the same time, energy savings can be realised with this intelligent solution. In addition, individual blasting programmes for new components can be easily created and saved. It is also possible to easily implement complex blasting processes with different blasting media quantities. One example of this is the desanding of cast parts, where a small amount of blasting agent is used to start with and then slowly increased. This ensures that the sand introduced is effectively removed from the abrasive and that the parts are cleaned as required. Compared to conventional sand removal processes, in which the turbines are usually switched on gradually, the cycle time can be significantly reduced. The Rösler PowerLine Valve also offers advantages in shot peening processes with short cycle times, as the adjustment times are significantly shorter than with conventional valves. The automatic monitoring and documentation of the blasting agent throughput is a further advantage. This makes it easy to prove that the blasting process has been carried out with defined parameters.

The new Rösler PowerLine Valve is available as an option and can also be added to the Rösler Smart Solutions package for system digitalisation.

About Rösler:

Seit über 80 Jahren ist die Rösler Oberflächentechnik GmbH als inhabergeführtes Unternehmen im Bereich der Oberflächenbearbeitung tätig. Als internationaler Marktführer bieten wir ein umfassendes Portfolio an Anlagen, Verfahrensmitteln und Dienstleistungen rund um die Gleitschliff- und Strahltechnik für unterschiedlichste Branchen. Auch die Auswahl aus ca. 15.000 Verfahrensmitteln, die speziell in unseren weltweiten Customer Experience Center und Laboren entwickelt werden, folgt der spezifischen Kundenanforderung. Unter der Marke AM Solutions bieten wir zudem vielfältige Lösungen und Dienstleistungen speziell für das Thema 3D-Druck/Additive Fertigung an. Als zentrales Trainingscenter vermittelt die Rösler Academy praxisorientierte Seminare zu den Themen Gleitschliff- und Strahltechnik sowie Additive Manufacturing. Zur Rösler Gruppe gehören neben den deutschen Werken in Untermerzbach/Memmelsdorf und Bad Staffelstein/Hausen weitere 15 Standorte und ca. 150 Handelsvertreter weltweit. Ausführliche Informationen unter: www.rosler.com