Meeting of the Technical Committee "Light Metal, Sand- & Gravity Die Casting" at the Foseco R&D Centre in Enschede, The Netherlands

The "Light Metal, Sand- & Gravity Die Casting" Technical Committee of the German Foundry Association (BDG) held its latest session at the Global R&D Headquarters of Foseco in Enschede, The Netherlands. The meeting, which took place from 13th to 14th October, included a social event nearby and a tour of Foseco’s state of the art R&D facilities.

Following a welcome by Dr Feikus, the program involved a series of lectures on latest developments and best practice in the light metal foundry industry.

Arndt Fröscher, European Product Manager for Non Ferrous Methoding at Foseco, talked about the latest developments in coatings for gravity die casting. The focus of this lecture was on new product innovations and the importance of using the correct application methods to achieve optimum results. The lecture was followed by a Q&A session addressing practical issues in the application of die coatings.

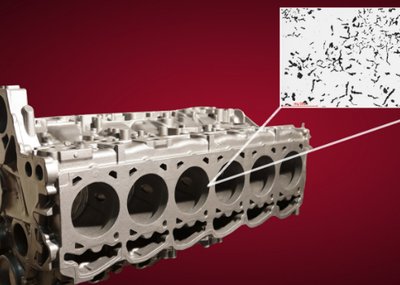

The final lecture session focused on the theme of "Melt Purity" and was opened by Kerstin Berndt, Product Manager for Non Ferrous Metal Treatment at Foseco. Her presentation " Melt Treatment - An Overview of Opportunities and State of the Art, with Practical Examples" highlighted the problems arising from oxides and their influence on mechanical properties (strength, elongation), which can lead to high scrap rates. Solutions to remove existing oxides and to prevent further oxide development in the melt were presented.

Pavel Holub, Vice President Research & Development, introduced the Foseco R&D department in Enschede and highlighted the importance of service and close customer cooperation. The lectures were followed by a tour of the R&D Centre, where employees presented Foseco’s innovative research facilities and demonstrated the test methods used.

The visit was augmented by a live demonstration of an aluminum melt treatment followed by a discussion, in which Kerstin Berndt answered questions from the technical committee. Jens Ohm, Business Unit Manager Non-Ferrous Foundry and co-organizer of the event commented: "The high professional level of the lectures and the presence of numerous decision makers in the specialist group led to a lively exchange of experiences, interesting discussions and new ideas. Once again it became clear that our customers still continue to focus on innovation, quality processes and productivity as highest priorities of their business. Our live demonstration was well received by the committee; it clearly demonstrated the importance of application experience and of understanding the production processes in order to generate high melt quality and product value by means of suitable products and services."

Partner

Foundry Corporate News

Topic Chemicals

Topic Coremaking

Topic Sand & Binders

Topic Moulding

Topic Pouring, Gating, Feeding

Topic Gravity diecasting

Topic Low-pressure diecasting

Topic Hand-mould casting

Topic Machine mould casting

German Foundry Association Technical Committee Visits Foseco R&D Centre

Reading time: min

[22]