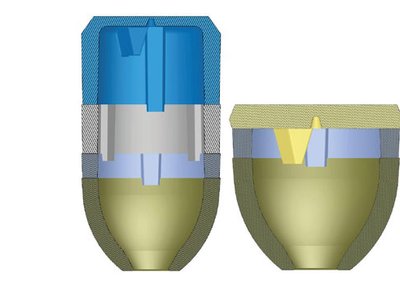

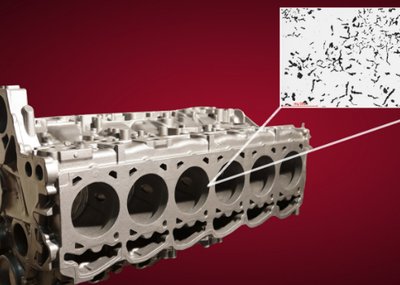

The current advantages, such as minimum footprint area, smallest contact area and optimum moulding sand compaction beneath were adopted from the existing FEEDEX K concept. From the first idea to the serial stage, extensive tests were carried out. Prior to casting tests, solidification simulations were conducted for verification purposes.

Within the new concept, a large part of the compressor core is heated by the highly exothermic feeder sleeve material.

• This significantly reduces the contact area of the compressor plate to the green sand by 50% compared to the FEEDEX VSK feeder. The result is an improved feed performance.

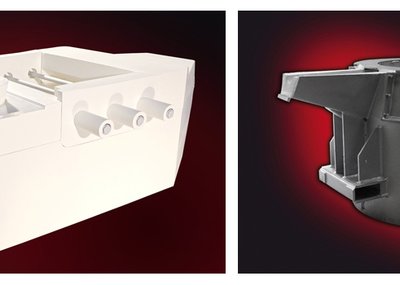

• FEEDEX K VAK feeders are used where smallest footprints and minimum contact areas are required.

• The application is as simple as with the VSK product line. The self-centring geometry eases the application of the feeder sleeve onto the fixed pin. Furthermore, the feeder residue can be easily knocked-off with little force.

The FEEDEX K VAK feeder series is based on the proven FEEDEX V-feeder product line.

Partner

Foundry Corporate News

Topic Pouring, Gating, Feeding

Topic Chemicals

Topic Refractories

Topic Melting Shop

FOSECO’s new FEEDEX K VAK spot feeder

Reading time: min

[13]