Enhanced requirements for component design and product quality make full-field, fast inspection for cast and forged parts necessary. This was the result of the exchange among experts at the GOM Workshop "Industrial 3D Measurement Techniques in Casting & Forging Processes," which was attended by more than 160 specialists in Darmstadt, Germany on 5th February 2014. The industry meeting was organized by GOM (Gesellschaft für Optische Messtechnik) from Braunschweig.

Presentations from users Trimet Aluminium SE, Mecklenburger Metallguss (MMG) and Tool Factory Raskopf demonstrated how 3D measurement techniques can be used to accelerate the entire process chain from design and simulation verification through to pattern and die construction as well as mold and core making, and ultimately casting and CNC machining. The companies reported shortened measurement and inspection times and therefore costs saved compared with the use of conventional tactile systems.

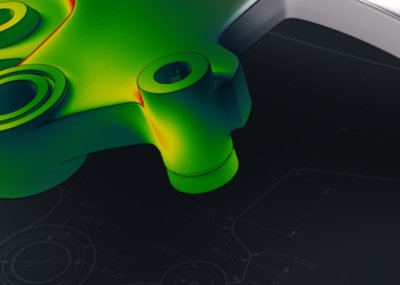

Optical measuring systems such as the 3D fringe projection scanner ATOS capture the complete surface of components instead of just a few individual measurement points. During evaluation, deviations from CAD data are highlighted in color, producing easy-to-understand corrections in clear measurement reports. This makes it possible to reduce several hundred pages of conventional tables from test reports to a handful of images and functional dimensions.

Alongside tool corrections, first article inspection and quality control of molds, cast & forged parts, the workshop focused on the latest developments in 3D metrology as well as the measurement and evaluation software. One new function, for example, makes it possible to track component movements in real time to enable exact alignment on CNC machines or pallets with an allowance control function. Another new function is back projection, in which the 3D sensor projects features such as isolines and punch marks straight from the software onto the part. This dispenses with the need to mark cast blanks by conventional means.

Another focus of the workshop was placed on the automated inspection of cast and forged parts. With its ATOS ScanBox, GOM has developed a standardized optical 3D measuring machine, in which the entire range of measurement and inspection processes, and even the test report, is executed automatically. In the software, GOM has also automated the measurement and inspection processes for components of identical design, thereby simplifying above all recurring measurement tasks.

###COMPANY_LINK### <link record:tx_browserdirectory_directory:4137 internal-link>![]() GOM, Optical Measuring Techniques

GOM, Optical Measuring Techniques