Green sand and aluminum share a rich history in the USA, particularly at Boose foundries, where the Boose family has been engaged in sand casting aluminum since 1933.

In 2006, Boose expanded its operations by acquiring the Cornwall Aluminum Foundry in Lebanon, Pennsylvania. Following a comprehensive upgrade of its manufacturing processes in 2019, the facility transitioned to operating under the name BQC Foundry, a testament to the positive changes in equipment, structure, and personnel implemented by Joe, LeAnn, and Brandon Boose.

Moving to DISA Quality

BQC Foundry currently runs three molding lines, all serviced by a single 100B Speedmullor capable of mixing up to 100 tons of sand per hour. Gravity pouring is the primary method for casting, executed predominantly by hand and occasionally with the assistance of robots.

In their pursuit of top-quality aluminum castings, the decision was made to replace existing molding lines with state-of-the-art machines. The shortlist of vendors was just that, short.

“I wanted to have the best green sand foundry on the US East Coast and, if possible, the entire USA,” says Brandon Boose, VP of Operations at BQC. “I figured the best starting point for that was to have the best molding machines. DISA has been the leader in foundry molding machines for decades and, in addition to simply wanting their machines, I have just always been a fan of DISA.”

High Expectations Satisfied with MATCH

In 2021, BQC installed its first DISA machine, the world's first DISA MATCH. Operating at speeds of up to 180 uncored molds per hour, with swift pattern changes of two to three minutes, the DISA MATCH 16/20 is ideal for foundries dealing with short, medium, and long production runs. Notably, its matchplate adaptor facilitates the reuse of existing pattern plates, contributing to cost-effective upgrades.

After two years of operation, the DISA MATCH has significantly enhanced BQC's ability to produce aluminum castings with high dimensional accuracy and impeccable surface finish.

“We consistently saw weekly scrap rates of 4-5% on jobs running on the old machines,” says Brandon. “That same product mix when switched over to the DISA machine runs less than 2% scrap on an average week, so our scrap percentages are a fraction of what they were before the DISA MATCH installation, which really is incredible. It’s even more impressive that it’s done this while producing up to 187 molds per hour.”

Boose Quality Castings: Laser-Like Focus on Quality

BQC can now effortlessly create precise molds, even for intricate designs, resulting in a thin parting line and minimizing the need for labor-intensive finishing processes.

“High quality molds with miniscule amounts of mismatch means our castings have a very thin parting line,” says Brandon. “There’s far less fettling and grinding required to satisfy our clients’ surface finish requirements which has reduced our labor costs significantly.”

“In the old equipment, we would have to put sand in the cope wherever there were pockets,” continues Brandon. “With the DISA, we just blow the mold. It’s impressive on the intricate pattern designs that we struggled with before too, that’s got a lot easier for us.”

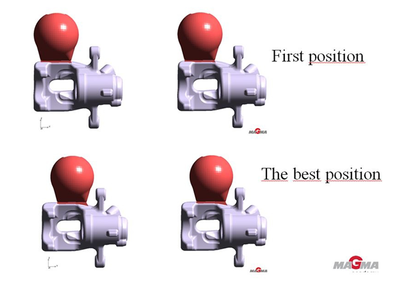

The company collaborated with DISA's Application team to optimize quality, yield, and productivity across a diverse range of castings.

Fast, Flexible, High Quality and More Sustainable: What’s Not to Like?

The benefits extend to the longevity and cost-effectiveness of green sand tooling, providing BQC a significant edge over die casting competitors. Green sand tooling costs are over 90% lower than permanent molds, with each plate having approximately six times the lifespan. The DISA MATCH's tooling durability aligns with the company's goal of achieving 100,000 molds.

“We primarily use DISA’s recommended tooling life,” says Paul Snyder, Quality and Engineering Manager at BQC. “Our most heavily used tooling has so far made 20,000 molds with no detectable tooling wear when inspected.”

There are sustainability benefits as well as low scrap rates contribute to reduced energy consumption. BQC also appreciates the eco-friendly features of the green diamond base sand, (non-silica), and the ability to reuse nearly 98% of molding sand.

More Business

Customers have recognized the cost and quality advantages of the DISA MATCH, enhancing BQC's competitiveness in the US market. The technology has enabled BQC to shift products from die casting to green sand, attracting a growing number of requests for quotes on previously die-cast components.

“We’ve now successfully helped customers switch quite a few products from die casting to green sand with the MATCH,” says Paul. “Bringing in the DISA technology has really opened up our playbook when it comes to quoting and engineering – how can we make this product cheaper and faster? From an engineering perspective, being able to make consistent molds and knowing how the sand’s filling makes our job a lot easier when we’re planning and quoting for a new product.”

"We can now quote jobs we’ve never been able to quote before, typically jobs that would go to die cast right away,” explains Brandon. “We can really compete against permanent molds or die cast, even with extremely challenging products with deep pockets and complex geometries. Since we can have the higher volumes at the same time, we’re able to keep the cost down for customers.”

With this performance, there is no surprise that BQC’s second DISA MATCH line was ready to start operating by October 2023. This time round, it’s the larger format DISA MATCH 20/24!

The success of the first DISA MATCH line prompted the commissioning of a second line, the larger format DISA MATCH 20/24, which commenced operations in October 2023. The continued adoption of DISA technology positions BQC as a formidable player in the foundry industry, capable of competing across various product types and complexities while maintaining cost-effectiveness and high production volumes.