The foundry industry is a prime example of a functioning circular economy. At the same time, it faces increasing pressure to significantly reduce emissions generated during casting. With the so-called BREF (“Best Available Techniques Reference Document”), the European Union set binding requirements for industrial processes in December 2024 to minimize environmental impact. For foundries and their suppliers, this means that emission limits are continuously tightened and processes must be constantly adapted—particularly with regard to emissions, energy efficiency, and resource usage.

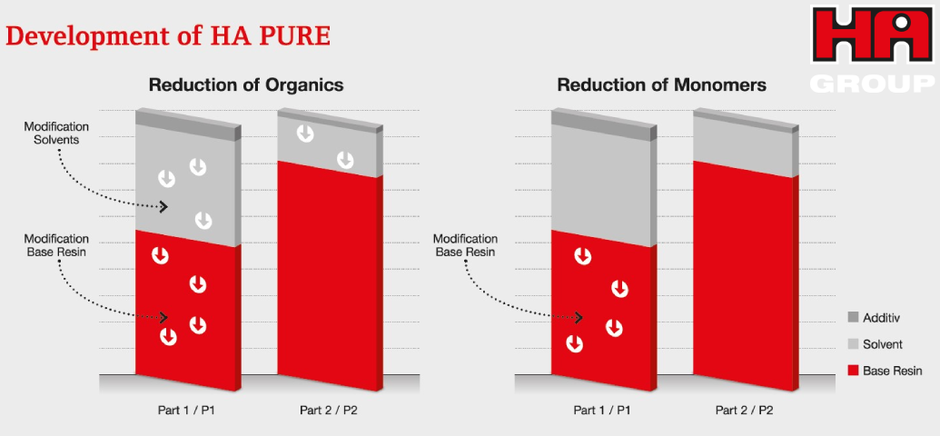

The HA Group has been working closely with its customers for years to develop innovative solutions that meet the rising demands for environmental and climate protection. With the new product line HA Pure, a significant step towards sustainability has now been achieved: the Cold-Box systems in this product family are based on a free monomer content of less than 1.0% (phenol/formaldehyde) and set new benchmarks for low-emission casting.

Challenges and trends in the foundry industry

Requirements in the industry are steadily increasing: components are becoming more complex, wall thicknesses thinner, demanding higher use of cores and more advanced binder technologies. At the same time, pressure is growing to reduce CO₂ emissions and participate in emissions trading schemes. Societal challenges—such as odor-related acceptance issues, a volatile global economic environment, and the shift in the automotive industry toward e-mobility—also play a role. This transformation brings numerous risks but also offers opportunities. One thing is clear: adaptability and continuous development are more important than ever, requiring innovative, sustainable products and processes.

The foundry as a circular economy

Traditionally, the foundry industry has been a pioneer of the circular economy, saving crucial resources by reusing scrap metal and recycling most raw materials. Foundry silica sand is a limited and valuable resource that should be used multiple times. Increasing requirements for the quality of used sand - such as phenol index, BTEX, TOC, and DOC - make sustainable sand usage increasingly important. The focus is on the modern “3R” principle:

- Reduce – minimize emissions and pollutants

- Recycle – recover sand from core and mold production

- Reuse – use sand multiple times and reduce disposal costs

HA Pure Systems: Innovation for greater sustainability

The new HA Pure product line supports the 3R principle through its low-monomer technology, featuring a free monomer content of less than 1.0% (phenol/formaldehyde). Designed as a technology platform, HA Pure enables targeted technical solutions within the Cold-Box product family to reduce emissions of phenol, BTEX, and formaldehyde. In particular, the reduced free phenol content significantly lowers phenol emissions and improves the suitability of waste sand for disposal. To further reduce VOC and formaldehyde emissions during the production process, the HA Pure system incorporates specialized “emission catchers.” The systems are compatible with all common Cold-Box solvent types and offer excellent storage stability as well as low odor during core production and casting.

Key advantages of HA Pure Cold-Box systems

- Free phenol content < 1.0%

- Reduced pollutant emissions (phenol, BTEX, formaldehyde)

- Lower phenol content in used sand

- Carbon- and VOC-reduced systems

- High strengths and excellent bench life

- Low odor emissions

- Compatible with all Cold-Box solvent types

Conclusion

With the introduction of HA Pure Cold-Box systems, HA Group sets a new standard for sustainable, low-emission foundry processes. The combination of innovative technology, resource efficiency, and practical implementation makes this product line an essential building block for the future viability of the foundry industry.