The Ortrander iron foundry in Germany is one of the pioneers in Industry 4.0 in the foundry. Additionally they investing in energy efficiency and process optimization.

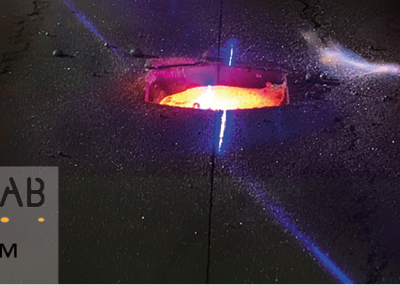

With Iron quality software from an Italian manufacturer each pouring ladle can be individually analyzed and optimized instead refer only continues with a lance sampling. The other innovations come from pour-tech, a Swedish specialist in Automatic Pouring Systems for Iron Foundries.

The aim is to obtain reliable data as a solid basis for decisions by the employee. At the same time they offer more stability, robustness and flexibility of the iron and the error rate can be minimized in the process.

Machines they are inform mutually and people take decisions on this basis secure the future and the location of Ortrander says CEO Bernd H. Williams-Boock.

Many individual machines are to be found in other foundries. But the core of Industry 4.0, to link them to each other and to gain from the obtained data by a usable database for higher quality decisions and further process optimization, which is unique in Europe.

Partner

Topic Pouring, Gating, Feeding

Foundry Corporate News

Topic Machine mould casting

Industry 4.0 at Ortrander

Reading time: min

[3]