StrikoWestofen at GIFA 2019: Presents the Connected Foundry

Ready for tomorrow's casting market: Industry 4.0 will once again be a key topic at this year's GIFA foundry trade fair from 25 to 29 June. This also applies to Norican Group's presence at the fair, which will feature its four technology brands StrikoWestofen, DISA, Italpresse Gauss and Wheelabrator. In Hall 11 (Booth A74-78), they will present the complete connected Norican foundry - powered by Norican Digital - on ca. 760 square meters from melting to surface finishing of the cast parts.

At GIFA, the world's leading trade fair for foundry technology, renowned suppliers will present proven solutions and pioneering innovations. Visitors to the Norican Group stand this year can look forward to a series of exciting solutions: The StrikoWestofen technology brand will be showcasing its innovations based on complete digital models and will also be giving technology insight presentations by its high-class experts.

Connected all along the line

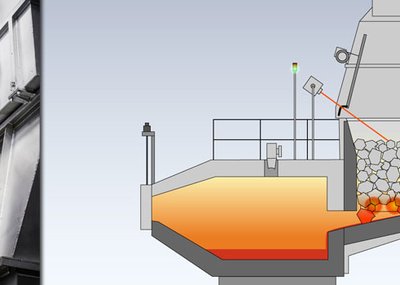

The StrikoWestofen exhibits range from the further optimized ProDos 3.3 dosing furnace control system via the "Smart Service Plan" with data glasses for real-time remote maintenance, an efficiency calculator for intelligent melting furnace solutions, through to digital models of the well-known StrikoMelter and Westomat melting and dosing furnaces. Visitors have the opportunity to experience the furnaces and their performance-enhancing options in a unique way. The digital presentation fits harmoniously into the orientation of the entire Norican Group: True to the motto "powered by Norican Digital", all the Group's technology brands will be presenting their digitally connected systems.

For this reason, all new StrikoWestofen systems leave the production line Industry 4.0-ready – pre-equipped to collect and provide informative data. If customers opt for a cloud connection, even selectable machine and production data can be displayed clearly and in real time with the browser-based "Monitizer" app. The app has comprehensive user management and pre-installed widgets that give the customer full control over data access and the data displayed.

Comprehensive data analysis enables foundries to achieve improvements in productivity, quality and resource control. The "Monitizer Starter Kit" allows retrofitting to any production machine, regardless of the manufacturer. At the stand, the possibilities of the "Monitizer" will be shown with live data from European foundries.

By networking its technology brands, Norican Group is focusing on good connectivity, because "Greater than the sum of its parts" is also the leitmotif of the full-range supplier.

Connectivity as the key to success

Theodoor van der Hoeven will be discussing the opportunities and limits of industry 4.0 and the latest technologies of the Industrial Internet of Things (IIoT), with a special focus on dosing accuracy, in his presentation at the GIFA Technical Forum. "Our trade fair motto is 'It's time to connect', says the Vice President Product Development at StrikoWestofen. "This relates to machine connectivity, but also to our intention to enter into discussions with foundry specialists from all over the world. We look forward to the opportunity to exchange the latest technical knowledge and discuss new needs."

Interested GIFA visitors will experience all the new StrikoWestofen technologies and lectures at the Norican Group stand in Hall 11, Stand A74-78.

Wheelabrator at GIFA 2019: a new wheel, advanced simulation technology and equipment evolutions

Surface preparation specialist Wheelabrator, a Norican technology, will be showcasing a suite of new blast machines and solutions at GIFA 2019, evolved and improved to meet emerging customer requirements and industry trends.

A host of updates and extensions to existing equipment ranges has been developed particularly with aluminium applications in mind – fitting in with the brand’s new stand location in the aluminium hall (Hall 11) at GIFA, as part of the Norican Group presence.

The Wheelabrator line-up for GIFA includes:

- a new heavy-duty Universal blast wheel

- a deep dive into the very latest blast simulation technology

- numerous machine innovations

Visitors to the Norican stand will also be able to learn about the latest digital developments, for Wheelabrator equipment and beyond, with experts from Norican Digital on hand to share the latest thinking.

A ‘best of’ in wheel blast technology

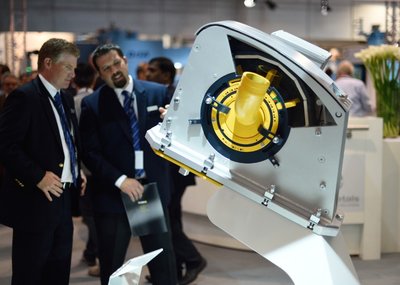

Wheelabrator’s new blast wheel for foundry applications will be unveiled at GIFA.

Representing the latest innovations and proven technologies from across the company’s global blast wheel range, the new Universal wheel has been refined in rigorous testing over the past 12 months. It will offer a new level of performance and productivity for foundry blast operations.

Simulating complex blast processes

Simulation of blast processes can speed up development of new machines and even inform the design process of the produced part – by testing buildability early on.

Working with leading manufacturers, namely in Automotive, as well as simulation specialists, Wheelabrator has been advancing blast simulation technology to enable the design of ever more complex parts and associated processes, particularly those with intricate internal surface areas.

At GIFA, Wheelabrator will show what is possible in blast simulation, including how advanced simulation techniques save time and money during part and process design – a key advantage in today’s ever faster product development cycles.

New machines for aluminium – and more

Also on show will be the latest machine developments soft-launched in recent months. They include extensions to and variations on existing ranges, which have been adapted to anticipate evolving customer requirements.

They are:

• The SPH-2-3/8, a new compact blast machine designed specifically for aluminium applications. Based on Wheelabrator’s trusted batch-type spinner-hanger wheel blast concept, the new machine excels at descaling, deburring/deflashing and cleaning of a variety of aluminium parts. Optimising the machine for this application enabled the design team to also reduce its price significantly.

• The LBS 1000, a lighter version of the LBS mesh belt shot blast machine range. The mesh belt concept allows the efficient blasting of parts from all sides within a relatively compact space and without tumbling. It offers pitless installation and a more ergonomic loading height. Like the new SPH, it is suited particularly to the processing of aluminium parts.

• A new range of wire mesh belt shot blast machines for medium-duty applications. The new CMS machine sits between Wheelabrator’s light LBS for non-foundry and the high capacity CMC range for heavy duty foundry applications. The CMS wire mesh belt machine completes Wheelabrator’s mesh belt machine offering. Mesh belt machines are perfect for applications where parts are too big or too delicate for the tumblast processes.

To find out more about Norican Group at GIFA, including technical presentations and pre-show content, please visit the dedicated GIFA page on <link https: www.noricangroup.com gifa external-link-new-window internal link in current>

.