With more than 95% of melting furnace operation costs resulting from energy consumption and metal loss, efforts to revitalise performance or embrace optimisation can be transformational – as car manufacturer Skoda discovered.

Given that the four StrikoMelter in use at its manufacturing plant in Mladá Boleslav, Czech Republic, were 15-years-old, Skoda opted to refresh them with an Equipment Modernisation Programme (EMP) from StrikoWestofen.

All four StrikoMelter systems were relined and retrofitted with an optimisation that revolutionised performance by unlocking new levels of efficiency.

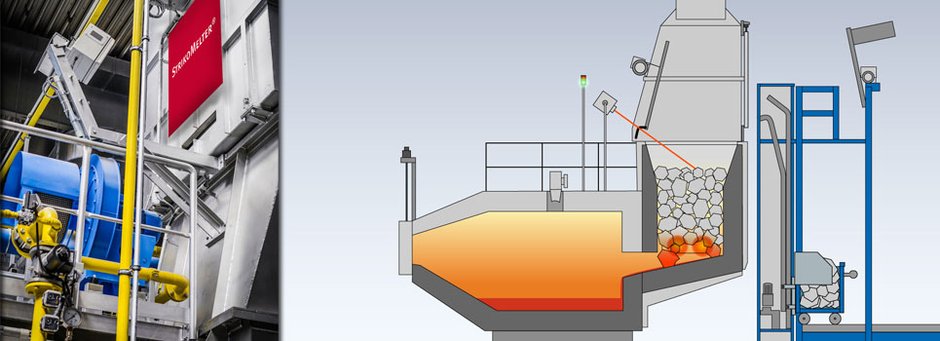

Level monitoring with laser precision

A melting shaft that is full at all times will achieve optimum energy consumption. This is because hot waste gases from the melting process are used to preheat the melting material in the EtaMax shaft prior to the actual melting process.

To deliver this benefit for Skoda, the EtaMax filling shafts of its 15-year-old StrikoMelter were retrofitted with laser technology. A laser beam scans the filling area of the melting shaft and permanently monitors the filling level. When there is no melting material left in the upper part of the shaft, the filling process is initiated automatically.

This optimisation reduces energy consumption dramatically: “The continuous filling of the shaft made possible by the integrated laser scanner has increased the energy efficiency to the point where we are able to reduce gas consumption by around ten percent per system,” explains Holger Stephan, VP AM Sales Support at StrikoWestofen. “The one-off purchase costs of this retrofit are usually recovered after only a few months. Today the laser scanner is one of the most frequently sold modernisation options, making it one of our bestsellers!”

All StrikoMelter systems can be retrofitted with the shaft laser. The StrikoWestofen’s furnace upgrade service offers a number of additional options designed to sustainably increase the performance level of existing systems.

To further optimise usage, made-to-measure training programmes can be designed to show operators how to get the most out of their melting systems with the help of optimum adjustment and the correct charging ratio.