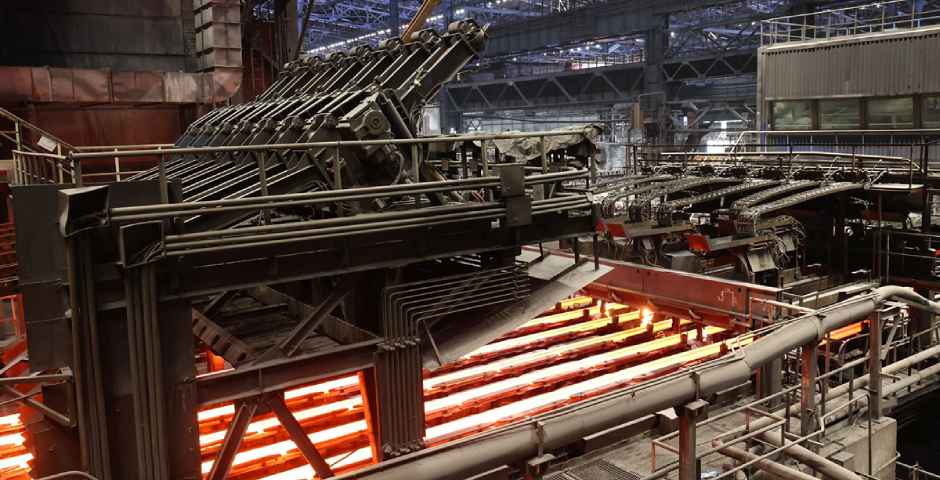

In the first eight months of 2025 alone, 58,430 tonnes were produced, already exceeding the result for the whole of 2024 by more than 5,000 tonnes. In July, the plant set a historic monthly record with 16,160 tonnes – almost twice as much as the previous year's high of 8,260 tonnes.

A key factor in this success was the optimisation of the automatic start-up process for stop casting. While the success rate of the ‘autostart’ mode was still around 80% at the beginning of the year, it now exceeds 90%. This has minimised human influence and ensured consistently high product quality.

Technical modernisation has also paid off: As part of the first conversion step of CCM No. 1, frequency converters, cables and lines were replaced and the software updated. The result: higher efficiency of the drawing furnaces and greater process stability during casting.

In addition, the average number of melts in stop casting was increased from 5.3 in 2024 to almost six per month. Kametstal is thus demonstrating how modern technologies can be consistently used to increase efficiency and meet the growing market demand for high-quality steel.

At the same time, the company has expanded its product portfolio: it recently successfully launched the production of 100 mm grinding balls with increased hardness – a key product for the reliable operation of mining and processing plants.

Source: Kametstal