The project team "New Blasting Machine" reported this in the spring of 2017 after about two years of operation. The SMART FOUNDRY thus achieves another milestone and is now able to radiate the entire spectrum of parts effectively and significantly faster. For customers, this means a shorter throughput time with improved surface quality.

After hall construction and roof sealing work had been completed, the spinning wheels, which are powered by eight turbojet turbines, turned for the first time at the end of March 2017. In the new shot blast machine, up to 16 tons of castings can be blasted simultaneously with a maximum diameter of four meters. The new blast system replaces the existing machine whose performance had reached its limits with larger component dimensions and higher surface quality requirements.

With the new system, the SMART FOUNDRY offers new possibilities to handle complex customer parts. Depending on the component design, the eight centrifugal wheels are individually controlled, and time intervals are defined for the treatment steps of sanding and blasting. As a result, the required surface quality is achieved for each component after the end of the process time - and this saves resources since the blasting material is thrown off the component only.

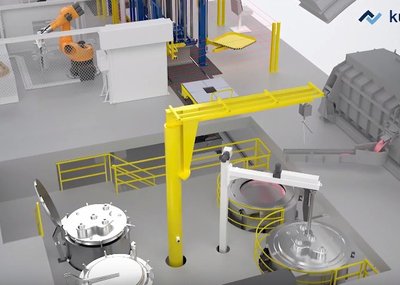

The blast machine was erected in close proximity to the existing production facilities in cramped conditions. When designing the process, creativity was needed. In order to achieve maximum capacity with an optimal part flow, the decision was made to have a crane system that allows hall transfers without needing to deposit the cast parts. Thus, the plant could be ideally integrated into the material flow, without affecting the ongoing operation during construction. Planning on a green field could not have produced a better result!