Magnesium alloys are processed in melting furnaces with extreme heat and large temperature fluctuations. If its core component (the crucible) fails, the entire casting cell comes to a standstill. RAUCH Furnace Technology (FT) has drastically reduced this risk by using a digital twin to monitor the crucible condition. Problems are therefore detected at an early stage, and downtimes are minimized using controlled measures.

Magnesium melt - How RAUCH Furnace Technology (FT) equips melting furnaces with innovative added values.

What do hydropower and casting technology have in common? Both are industries with a long tradition of having great forces at work. They are also considered to be conservative and often underestimated when it comes to topics such as digital transformation. But this is not the case. VERBUND, for example, operator of Austria’s major hydropower plants, has been digitally safeguarding the operational readiness of its plants for years.

For this purpose, real sensors feed the digital images of critical components with real load data. Virtual sensors at critical points allow the evaluation of the occurring load and the assessment of wear. If defined limit values are reached that signal a failure, technicians can quickly take care of maintenance or replacement without complications.

Many are still talking about “digital twins” – VERBUND has already implemented them together with its partners ITficient and CADFEM.

Another link to casting technology was created in 2019 at the CADFEM Conference in Linz. The presentation of the VERBUND project impressed Florian Sipek (physicist at RAUCH FT, the Austrian specialist for melting technology) so much that he transferred this knowledge to his own products and also inspired his colleagues with this idea. However, this is not surprising, since innovation and the courage to explore new paths are part of the DNA of RAUCH FT. These qualities have contributed to the highly specialized company becoming the world leader in melting technology. The company takes pride in being considered the world market leader for Mg melting systems.

Florian Sipek

Head of R&D, RAUCH Furnace Technology

Even in a sector as rich in tradition as the casting industry, we are using the digital twin to drive digitalization forward, and we are reaping the Benefits.

ABOUT RAUCH FT

RAUCH FT stands for high-quality melting technology solutions for magnesium, zinc and non-ferrous metals that integrate perfectly into individual production processes. Know-how from research and experience in the implementation of complex systems ensures sustainability and reliability over several production cycles. The RAUCH FT team is characterized by the highest quality standards and absolute cost awareness, as well as the trusting, long-standing relationship with its business partners. www.rauch-ft.com

67 employees at the company headquarters in Gmunden, Austria

45 countries worldwide – the sales region of RAUCH FT

2,2 Mio. tons of melting capacity is provided by RAUCH FT products

DIGITALIZATION TO THE EXTREME

Melting furnaces have their work cut out for them. When metals are melted, recycled, and alloyed in these furnaces, the temperature can reach up to 2,000°C, gas flows can reach speeds of 1,000 km/h and load changes are the norm.

Greater reliability of melting systems is extremely valuable for operators. If a system suddenly comes to a standstill, there is not only a risk of damage to the furnace, but also of serious production delays or failures. In the worst case, employees could be put at risk.

The idea: Digital twins should significantly reduce such dangers by identifying problems at an early stage. RAUCH FT strives to provide customers with valuable insights during ongoing opeartion, which includes alerting them to maintenance or cleaning needs.

If a melting furnace suddenly breaks down, the consequential damage for our customers is often serious. The significantly lower risk with our systems is a real competitive advantage.

Hannes Viertbauer, Sales Manager, RAUCH FT

DATA AND SIMULATION KNOWLEDGE PERFECTLY ORCHESTRATED

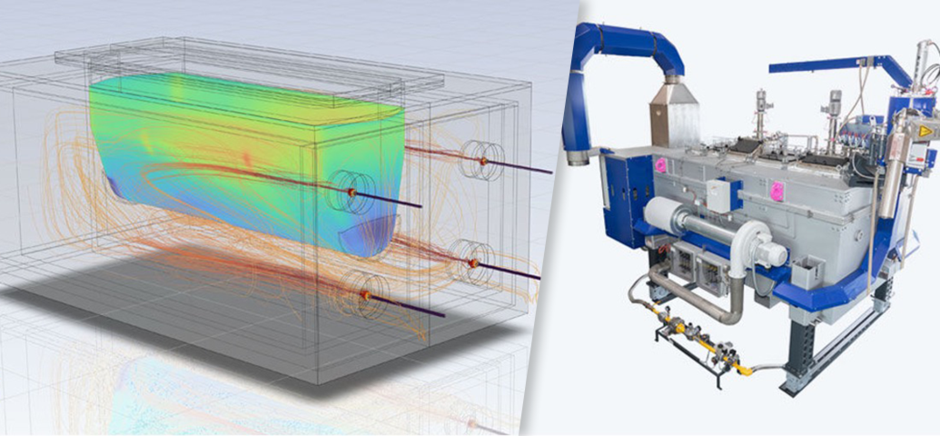

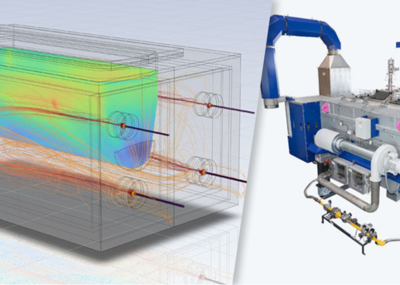

There are still no comparable approaches in casting technology. RAUCH FT, together with ITficient and CADFEM, has tackled the challenge head on, just as the trendsetters at VERBUND did. ITficient for data management, business model and IT architecture; CADFEM for all simulation, from flow to various transient and nonlinear structural mechanics applications and sensitivity studies to system simulations including condition monitoring.

RAUCH FT was well prepared for the digital twin. Many systems and components are already being simulated. The majority of these simulations deal with fluid mechanics. The spectrum ranges from transient cooling and heating processes to processes in dosing or flow pumps to chemical reactions.

In addition to a powerful IT infrastructure, there is already a large data pool available for the system via remote maintenance. The evaluation of this data provides valuable insights into the operation of the furnaces, which are also incorporated into the digital twin.

Teresa Alberts

ITficient AG

The implementation of digital twins is independent of an industry. It is based on data, physics and the customer's product knowledge.

HOW LONG WILL THE CRUCIBLE LAST?

The ideal component for the first practical implementation is the crucible. The welded steel construction is highly loaded. As Florian Sipek explains, “2000°C hot flue gas on the outside, corrosive protective gas, and hydrostatic pressure of up to 4t melt on the inside. You also have extreme temperature gradients, the radiative power of the flame and high velocities with inhomogenously distributed radiant energy”.

If the crucible fails, the system comes to a standstill. Maintenance is usually based on experiential values, which, in an ideal world, can be beneficial. But as soon as irregularities occur in the processes or during handling, there is a risk of failure and thus consequential damage. “This is precisely when the value of predictive maintenance becomes apparent,” summarizes Florian Sipek.

Christian Abramowski

Technical Manager Hanover, CADFEM Germany GmbH, Hanover

Digital twins are an important symbiotic extension of reality through simulation.

EXAMPLE: INFLUENCES OF SEGREGATION

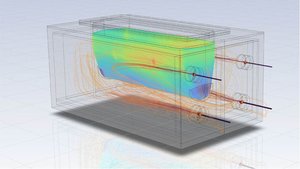

The idea of digital condition monitoring of the crucible is an interplay of real measured values and virtual sensor technology. Due to the segregation that occurs in the melt (i.e., the deposition of certain compounds), a sludge forms at the bottom of the crucible. This leads locally to a change in the flow conditions and the material parameters of heat conduction and heat capacity, which disturbs the heat transfer at the bottom of the crucible from the furnace chamber to the melt. In connection with the inhomogeneous temperature distribution on the outer wall, high stresses arise in the crucible.

The sludge volume is therefore an important boundary condition for a correct prediction of the real-time load on the crucible as well as for the reliability of predictive maintenance. Due to the environmental conditions in the crucible and in the furnace, the use of real sensor technology for temperature measurement is hardly possible. Therefore, CADFEM's concept provided virtual sensors for the simulations. Together with a sump quantity calculated from the temperatures and the process parameters, a local load on the crucible can thus be concluded with only a few measuring points and input variables.

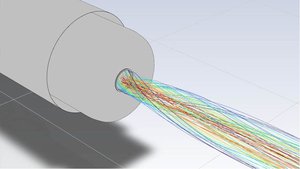

Precise modeling of the temperature distribution in the furnace chamber by computational fluid mechanics (CFD) and of the stresses at the weld seams (structural mechanics, FEM) are essential for predicting the remaining life cycle of the crucible. On the CFD side, a combustion simulation of the burner and the furnace chamber is performed for a correct prediction of the flame temperature, the heat radiation, and the momentum input. Based on the CFD results, a temperature field and a stress analysis are performed using the melt as a variable heat sink to represent the melting of ingots thrown in.

IN EVERY INFRASTRUCTURE

The digital twin must be adapted to the individual requirements of the end customer – both in terms of the processes to be modeled as well as the IT infrastructure to be used. A concept for IT integration is an important building block in the implementation, including the handling of sensor data, the operation of the twin, security and network issues. ITficient was able to build on a data pool and an IoT platform at RAUCH FT.

The necessary microservices – receipt of sensor and machine data, calculation of virtual sensors, models and processes, data storage and evaluation, and visualization of results – were integrated in such a way that IT resources were optimally utilized, no isolated solutions were created, and RAUCH FT retained full control over all processes in its hands, meaning that it could also develop them further independently.

ITFICIENT AND CADFEM

A powerful digital twin has two essential layers: Accurate simulations and a reliable IT infrastructure. The project will be successful if both sides mesh with each other. RAUCH-FT was able to achieve this because CADFEM and ITficient, two partners with a great deal of experience in their respective fields, were involved. At the same time, they are in close and trusting exchange, as they are both closely linked organizationally as companies of the CADFEM Group.

The third member of the group is RAUCH FT, supported by its pilot customer Georg Fischer Casting Solutions. With the digitally monitored melting furnace, RAUCH FT achieves more occupational safety for its employees. In-depth product knowledge, openness to new things, strong communication, a clear idea of what was to be achieved and the participation of all departments in the project were the keys to success. Existing competences were integrated. Some tasks were carried out cooperatively, others as a pure service by CADFEM or ITficient - always in the sense of the defined goal of a complete know-how transfer to RAUCH FT.

The crucible was only the starting point. RAUCH FT intends to scale the acquired skills for planning, construction and management of a digital twin and in the future provide all relevant components such as metering pumps, heating systems or circulating pumps and entire systems with digital solutions for predictive maintenance, thus setting standards for casting technology and customers like Georg Fischer.

About ITficient:

ITficient, a CADFEM Group company, supports companies on their journey to digital solutions such as predictive maintenance through Digital Twins. From onboarding to implementation and scaling, it's about working with customers to find and follow the best path to their digitalization goals. www.itficient.com

Both occupational safety and effort are improved by the digital twin. This makes GF casting solutions attractive as an employer, especially in times of increased staff shortage.

Andreas Thaler, Head of Operating Technology GF Casting Solutions Altenmarkt

This vision does not end with our own products. A classic die casting cell not only consists of the melting furnace, but also of other components from various manufacturers. Be it robots, presses, heating/cooling units or the die casting machine itself, almost every component in the foundry has the potential for a digital twin.

A start has been made: By RAUCH Furnace Technology (FT).

A DIGITAL TWIN NEEDS LOVE ... TO THE DETAILS

Stakeholders: Who in the company is affected?

Perspectives: What are the challenges, what are the added values?

Personas: Who are the future active users?

Prioritization: Which use case is suitable to start with?

Technical analysis: Which models, sensor data, IT infrastructures are available?

Recommendation: A moderated intensive workshop with in-depth analysis of requirements, goals and prerequisites has proven to be the basis for a successful Digital Twin project. This is followed by a rough concept of the use case, detailed proof of concept, implementation, and scaling to other use cases. workshop(at)itficient.com

Visit RAUCH Furnace Technology GmbH at EUROGUSS 2024 at Hall 9 / Booth 9-617