Cast aluminum components offer tremendous lightweight construction potential. New methods for sand mold and sand core production enable increasingly complex cavities and casting structures. In addition, there is the trend towards electromobility in the automotive industry. New castings are finding their way into high-volume production. Fill has set itself the goal of optimizing the low-pressure casting technology successfully established in the marketplace.

The innovation originated from a successful development project to improve the control and regulation technology for low-pressure casting machines. At the same time, the potential of decelerating the filling speed at the molten metal ingress, i.e., active braking and thereby calmer filling depending on the shaping of the cavity, was assessed. The pressure curve is modified subject to the height relative to the furnace bath level. Lowering of the furnace bath level must be compensated for in the control system. The filling level and the rate of pressure increase relative to the cross-section yield the volumetric flow rate that sets in once the molten metal is forced upwards by the overpressure in the furnace. Expansion of the cavity therefore results in a rise in the aluminum conveyed through the riser pipe. If the molten metal level remains constant, the flow velocity increases. Expansion of the cavity, especially after the sprue bush, consequently results in a considerable increase in flow velocity in the riser. This increase leads to turbulence in the molten metal. In order to nevertheless achieve particularly low-turbulence mold filling, the molten metal must be actively decelerated. In the opinion of experienced casters, casting sieves that hold back oxides also perform particularly well in decelerating the molten metal. This means that a casting sieve can equally be interpreted as a mechanical flow retarder. However, the sieves generate costs in the low-pressure casting process, on the one hand due to the sieves themselves, on the other due to automation of sieve setting and subsequently due to machine tools for drilling out the sieves. Depending on the material, it may be possible for the infused sieve to be melted down in the return scrap material. Otherwise, it has to be disposed of. The solution is an active flow retarder that can be integrated into the regulation and control technology. This means that the casting sieve can be omitted if it only serves to decelerate the molten metal.

Braking effect of eddy currents in the molten metal

Moving an electrical conductor – in this case aluminum through a magnetic field – causes eddy currents to be generated in the conductor, which decelerate the molten metal due to the opposing field formed. The effect of this eddy current brake depends on the speed. If the flow velocity in the riser increases, so does the braking effect. When the cross-section of cavities changes significantly normal to the filling level, the magnet box decelerates the molten metal and low-turbulence mold filling ensues. This effect is self-regulating and enables low-turbulence mold filling, irrespective of complicated pressure curves that have to be adapted to the cavity. In addition, the magnet box compensates for errors that result from shifts in the pressure curve depending on the filling level. For example, a changing furnace geometry and molten metal withdrawn through the casting lead to a deviation in pre-compression and the filling level. This shifts the pressure-change points vertically and makes them deviate from the points in the casting system. The magnetic field is controllable. This means that it can be activated and changed in a field strength from 0 to 500 mT. This possibility enables targeted influencing of the casting process. For a defined braking effect and casting process, it also allows permanent magnets to be used. This option offers great potential for series production of the same or similar castings. Figure 2 shows the reduction in flow velocity in the riser pipe over time at a constant rate of pressure increase. The entry to the die is indicated on the time axis. The riser pipe with an inner diameter of 60 mm expands into a cavity with an inner diameter of 200 mm. The magenta line B=0 indicates an overshoot and an increase in average flow velocity in the riser to over 500 mm/s at a constant rate of pressure increase of 7 mbar/s. With an activated field, the braking effect results in a reduction compared to the maximum to 270 mm/s without any overshoot.

Short-circuit current

As well as the eddy current brake caused by the magnetic field, the magnet box from Fill has been designed such that a short-circuit current transverse to the magnetic field can be sent through the molten metal. The current density caused by the short-circuit current in addition, perpendicular to the magnetic field, increases the braking effect on the molten metal to a significant extent.

The ideal braking effect under short-circuit current can be seen in figure 3. A permanently applied short-circuit current induces a time lag in the braking effect due to the field (blue line). If, on the other hand, the short-circuit current is ramped up linearly from the die ingress to 200 amps, as shown in figure 3 (orange line), this yields an even greater braking effect that can be activated by the magnet box. The technical design permits magnetic flux densities of up to 500 mT and short-circuit currents up to 400 A.

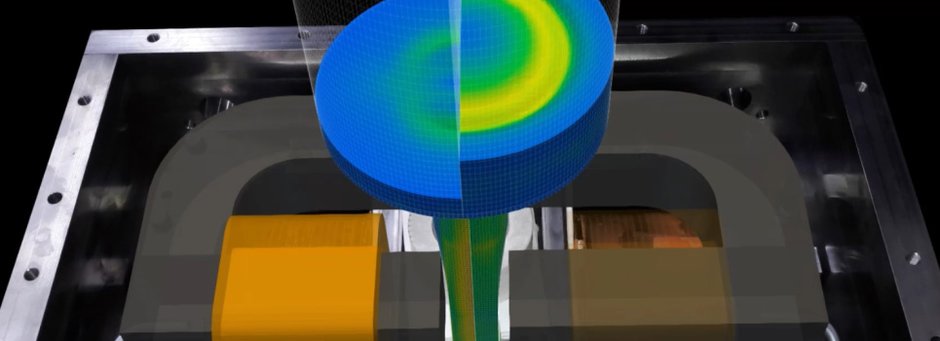

Simulation of the new process parameters

Due to the new process parameters of field strength and short-circuit current and their regulation, in addition to the pressure increase in the new magnetic induction casting process, a simulation of the magnet box has been developed. The HZDR Helmholtz Center in Dresden-Rossendorf used OpenFOAM as a basis to develop implementation of the magnetic field and short-circuit current. Figure 5 shows the simulation of the casting process in a cylindrical cavity, on the left with braking effect, on the right without braking effect. The simulation enables optimization of the process parameters.. Components that indicate oxide inclusions or critical areas in the filling simulation can be optimized using this tool. The aim of the magnet box is to improve existing products and raise the quality rate. In the case of new products, simulation of the casting process enables improvement through virtual testing and determination of the optimum casting parameters. This allows problematic areas to be identified at an early stage and solutions to be found thanks to additional options in the process.

Benefits, environmental impact, and outlook

In combination with the technically higher quality of systems, the following benefits can be expected:

- Less scrap thanks to better component quality

- More efficient resource utilization

- Lower auxiliary material consumption (for example, thanks to omitting the large sieve)

- Optimizable control technology

The magnet box is currently being further enhanced to act as a sensor to supply data about the actual filling speed. This means that it should be possible via production data acquisition, in addition to the conventional machine data, to gain a detailed insight into the actual process in future. A fully equipped Fill low-pressure casting machine with magnet box has been made available to SRI d.o.o. in Slovenia for test and small-scale casting operations. Due to the innovative technology, independent research center Access e.V. (RWTH Aachen University) is likewise banking on collaboration with Fill. The focus here is on low-pressure casting in complex precision-casting dies. There is great potential in this planned cooperation, particularly in the integration of digital simulation tools.

Acknowledgments

This development was supported by the Austrian Research Promotion Agency (FFG) (no. 869684). Special thanks go to development partners HZDR Helmholtz Center Dresden-Rossendorf, Department of Magnetohydrodynamics, particularly Dr. Vladimir Galindo, Bernd Willers, Dr. Dirk Räbiger, and Dr. Sven Eckert for their expertise in the areas of magnetic fields, smelting, and simulation, as well as the Director of the SRI d.o.o. foundry, Silvo Rihtarič, for his commitment and experience in implementation and testing.