Casting burrs or other protrusions are simply knocked off by means of rotating, specially developed impact knives.

The individual mounted impact blades are made of very resistant powder-metallurgical tool steel and guarantee maximum service life. The castings are brought to the rotating knock-off wheel by means of a robot or a manipulator. Depending on the design of the gripper, all sides of the casting can thus be freed from burrs, sprues, pins, etc. Depending on the system concept, a robot-guided deburring wheel can also be implemented. The predeburring of the components also increases the service life of the possible subsequent grinding process, as the result is a constantly constant residual burr height. Depending on the thickness of the burrs, the deburring wheel can also take over complete deburring and completely replace the grinding process step.

YOUR ADVANTAGES

- High flexibility

- Deburring of castings "in the black"

- Long service lives

- Low tool costs

- Burrs up to 100 mm in height can be removed.

- Low investment costs

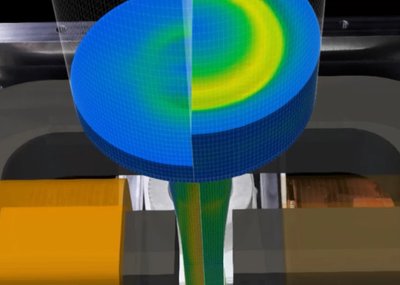

THE PRINCIPLE

The parts are brought up against the rotating deburring wheel by a robot or manipulator. Burrs, sprues, pins, etc. can be removed from all sides of the casting, depending on the design of the gripper.

Deburring of the parts increases tool life in any subsequent grinding process, as it results in a constant residual burr height.

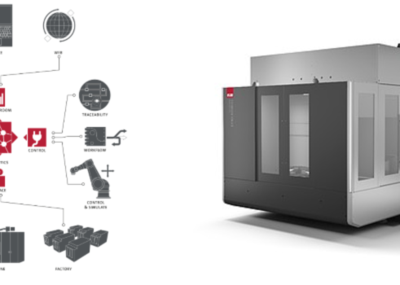

The deburring wheel can be operated either as a standalone machine or in combination with several machines, as required.