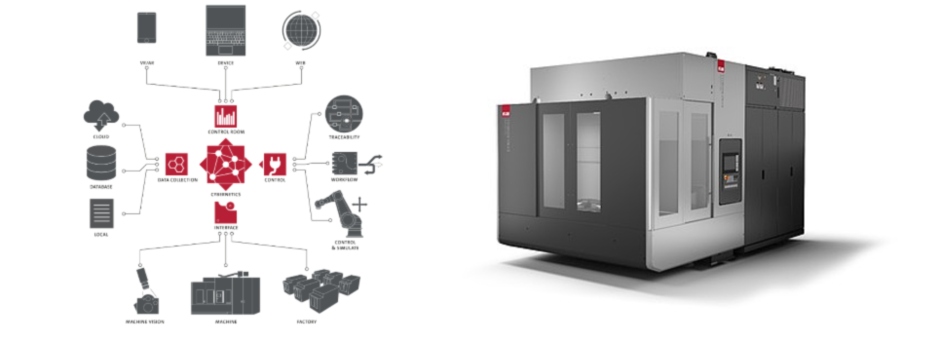

The Fill Future Zone was a hotspot for innovation at Euroguss in Nuremberg from 14 to 16 January 2020. The Upper Austrian company demonstrated how digitalization is now really possible in all areas of a company. Fill Cybernetics connects to all the machines and systems in a factory and enhances them with intelligent algorithms. The clever process control system optimizes not only component flows, but also plant capacity utilization. Another new development presented was magnetic induction casting. This innovative process enables extremely low-turbulence casting.

"The symbiosis of virtual and real processes opens up completely new opportunities. Production planning, material utilization, productivity, and reliability are raised to a new level," says Thomas Rathner, Head of the Casting Technology Competence Center.

Visitors to Fill’s exhibition stand were able to see how these innovations work in practice. The syncromill c22-63/600 machining center for castings and magnetic induction casting were further highlights at Euroguss 2020 in Nuremberg.

Experience and innovative spirit

Fill is able to draw many years of experience in gravity, tilt, back-pressure, and low-pressure die-casting. In order to guarantee precise production processes and high quality levels, the optimum interplay between the filling process and die movement is central to our concepts. This is also the case with magnetic induction casting, presented for the first time at Euroguss. In this process, a magnetic field is established at the end of the riser during die filling, and electrical contact is also established. This slows down the molten aluminum as it enters the die, and a laminar, smooth molten flow without turbulence is created.

Meeting point for the international foundry industry

Once again, the Fill exhibition stand at Euroguss became a communication platform for the international foundry industry. The machine engineering experts from the fields of casting and metal machining technology were very pleased with the active interest and specific inquiries regarding the latest foundry solutions made by Fill. Many new contacts were established and existing ones strengthened over refreshing cocktails with Austrian hospitality.