As it is known, Meccanica Pi.Erre is leader in the Trimming Technology and of course, it is leader in trimming of structural elements too. In this regards, the most popular and made ones so far are the suspension parts, generally called Shock Tower, Langsträger or side member, cross-members of axles, instrument panel, that is dashboard frame.

Meccanica Pi.Erre has been dealing with trimming of this sort of components for more than 15 years, being Meccanica Pi.Erre the first company who started to trim structural shots in Magnesium, such as instrument panel and seat frames.

Structural components in Magsimal and Silafont aluminum alloy should be considered as the new challenge and frontier of HPDC; nonetheless, only main OEM and TIER1 have been currently and strongly committed to the production of this kind of components in light alloy. Most of these parts are in fact still manufactured in steel.

The replacement of steel structural components with the aluminum ones has as result a more competitive production cost. Moreover, this leads to the important goal of “save weight”, contributing the lightweighting of vehicles. This is a very popular aspect during last years, because this means a less consumption and lower carbon dioxide emissions.

The productive process of structural components must be of high level, so that it can be defined as HTP, “High-Tech Process”. In this process, trimming operation must necessary be of high technical level and of high technological content too.

Said that, production of structural components must take place in die casting plants, fully automatized and interlocked by robot; thus, trimming solutions – in particular trim dies and trim presses – must in turn have a specific configuration.

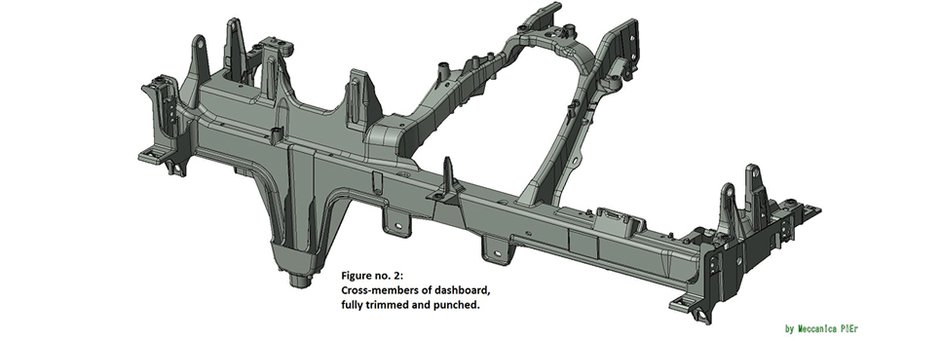

In fact for what concerns structural shots, trim tool and trim press are designed and made by Meccanica Pi.Erre in order to clearly provide a full trimming of outer and inner profiles, of holes, of gate, of overflows, and of chill-vent channels. This operation must ensure at the same time the ejection of chips at each cycle. This a very determinant aspect for the running of die casting cell.

Furthermore, Meccanica Pi.Erre pays particular attention to the interface between trim tool and trim press, as well as to the entire cell configuration. This not only to gain a complete trimming, but also and mainly to turn a raw shot into a semi-finished piece, ready for machining operations.

This absolutely avoids any damaging and expensive operations of manual re-work, which of course would negatively affect process and production costs.

Partner

Foundry Corporate News

Topic Discharging, Decoring, Fettling, Finishing

MECCANICA PI.ERRE, PROTAGONIST IN PRODUCTIVE PROCESS OF STRUCTURAL COMPONENTS

Reading time: min

[5]