Global casting giant MAT Foundry Group has chosen DISA’s Artificial-Intelligence-powered Monitizer | PRESCRIBE tool to reduce scrap. Operating seven foundries across three continents, MAT Foundry Group casts over 500,000 tons of iron every year and is one of the world’s biggest manufacturers of car parts.

The initial test site will be MAT’s EURAC facility in Poole, UK which produces over 40,000 tons of iron castings annually. The EURAC Poole site is a longstanding DISA customer and has used the Monitizer | DISCOVER solution for data collection, data visualisation, real-time monitoring and alerting since 2016.

“Our main goals are to reduce scrap and make our process stable,” says Shaun Lindfield, Commercial Director at MAT Foundry Group. “We already have collected and centralised huge amounts of data with Monitizer | DISCOVER that we exploit daily. If the project is a success – and I am sure it will be – we intend to implement PRESCRIBE in other foundries across our global group.”

Boosting profitability, perfecting processes

EURAC Poole will deploy Monitizer | PRESCRIBE across both its two DISA lines to maximise casting quality. Previously proven to reduce scrap by at least 40% and powered by Norican’s award-winning Artificial Intelligence (AI) partner DataProphet, Monitizer | PRESCRIBE harnesses cloud computing and AI to optimise an entire process. By analysing live data, it can recommend changes to process parameters that prevent defects occurring.

“Our long partnership with DISA and other foundries’ successful PRESCRIBE deployments give us confidence that this technology is well proven and the correct next step in our digital journey,” says Shaun. “In fact, this project is very low risk for us. Monitizer | PRESCRIBE uses the same platform as our existing Monitizer | DISCOVER tool and has sensible upfront pricing with ongoing subscription-based payment.”

Data is already being loaded into the AI and model being build, with the first test runs scheduled for mid-2022. Driving down scrap will boost EURAC Poole’s profitability and, thanks to lower energy consumption, improve sustainability performance. PRESCRIBE’s automated suggestions will also help fill a potential knowledge gap at the foundry.

“We lose a huge amount of expertise when older staff retire,” says Shaun. “Upskilling takes training and time. PRESCRIBE will analyse our historical data to learn which inputs work best and will guide us in adjusting our process to reach the best possible quality. Not letting operators work by trial and error will reduce process variability too.”

Quick, powerful data collection and visualisation

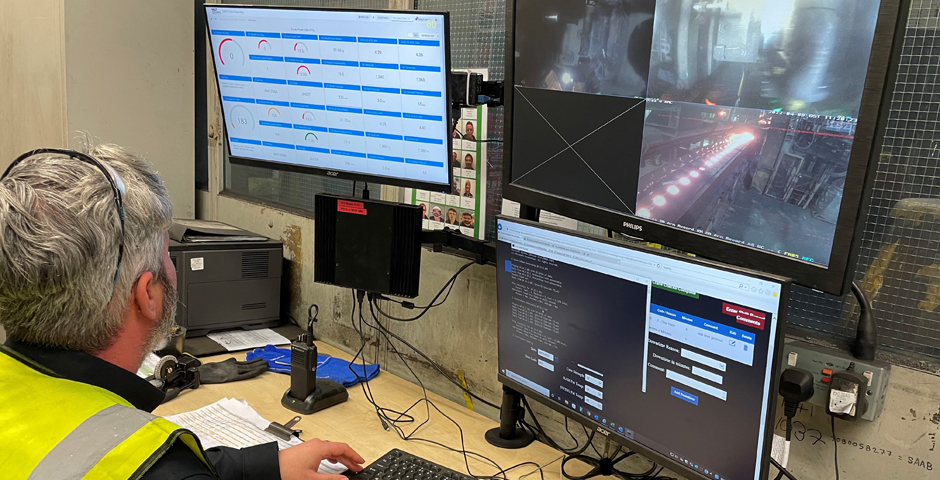

Using DISA’s NoriGate gateway, EURAC Poole has connected Monitizer | DISCOVER to more and more equipment over the last six years to create a real-time, data-based view of its entire process. Managers view critical KPIs within customised dashboards while other staff can now access information on the factory floor. For example, a large screen in the core shop displays shift targets for core production and whether workers are on track to reach them.

“We had considered data capture projects in the past and it was always huge amounts of money,” explains Shaun. “But deploying NoriGates is very quick and affordable, you simply plug into any PLC or other data source to pull the data out, and they don’t have to be DISA or Norican machines. That’s a big advance. Then you have the simplicity of a cloud platform where all your data is ready to analyse. And it’s easy to create your own dashboards and set up alerts.”

The UK’s experience has inspired other digital projects at MAT Foundry Group, such as the successful implementation of Monitizer | DISCOVER at the Mincer facility in Mexico. EURAC Poole collaborates closely with DISA and other Norican brands like Wheelabrator to make the most of the latest technology as it becomes available. For example, DISA’s Remote Smart Service (RSS) delivered expert technical support via real-time video streaming during Covid.

“When it was impossible for people to travel, using RSS to get a virtual visit from an engineer to diagnose equipment issues was invaluable,” says Shaun. “DISA doesn’t have any real competition in the moulding line sector but they don’t sit back, they are always driving the technology forward. They are our most reliable and innovative supplier. Because I trust the DISA team to deliver on what they promise – like they always have – I know Monitizer | PRESCRIBE will give us the improvements we are looking for.”

For more information, please visit:

https://www.disagroup.com/en-gb/foundry-products/digital-solutions/monitizer/monitizer-prescribe

https://www.disagroup.com/en-gb/foundry-products/digital-solutions/monitizer

About DISA

DISA, a Norican Group technology, develops and manufactures a complete range of metal casting production solutions for the ferrous and non-ferrous foundry industries. Headquartered in Taastrup, Denmark, DISA is the world-leading supplier of complete foundry solutions and services, as well as state-of-the-art green sand moulding equipment.

DISA also offers its class-leading Monitizer digital solutions, developed in partnership with Norican Digital Lab, that support the whole digital journey from data collection to AI-driven casting quality optimisation. Monitizer works in all types of foundries and processes, and with any vendor equipment, to deliver serious process improvements – fast.

http://www.disagroup.com