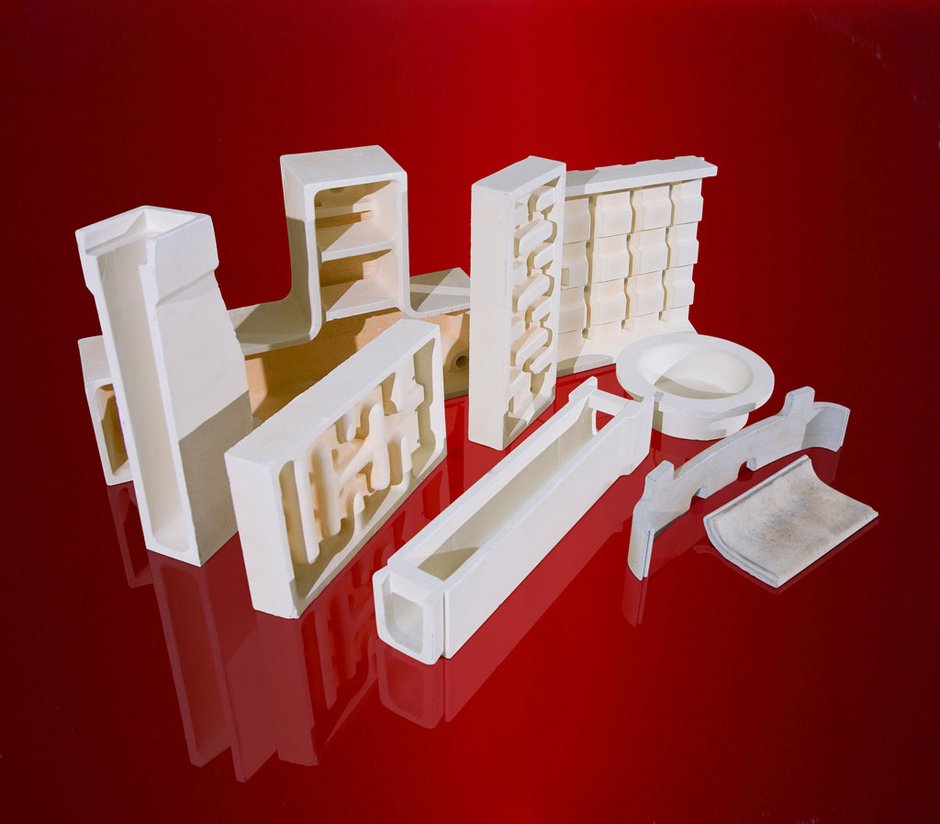

Morgan Thermal Ceramics announces the availability of Cerox® fired refractory shapes, offered in a range of material compositions, including many specifically used for the manufacture of rotating and non-rotating airplane components and automotive turbochargers. Dense, hard, and chemically stable, Cerox fired refractory shapes offer resistance to chemical attack from acids, slags, and gasesto produce the cleaner, contaminant-free metal desired by end users in aerospace and automotive steel foundries. They are manufactured at facilities in Cañon City, CO, and Augusta, GA, where product managers and engineers are centralized to ensure superior customer service.

Fired shapes manufactured from Sillimanite Cerox 200 are composed of 74 percent alumina and fired mullite, which are prized for their chemical attack resistance, good thermal shock, and excellent non-wetting characteristics at temperatures as high as 2850°F. Other materials available include Cerox 700 which has a high alumina content as well as versatile shape capability, making it ideal for products with complex shapes, including crucibles, tundishes and launder systems. For complex shapes, Cerox 720 which also features high alumina content is particularly adapted to developing shapes with thin walls, due to its fine grain and high strength.

Cerox shapes are fired to temperatures that create especially strong molecular bonds, making them superior in applications required to produce clean and contaminant-free metals. Combined with precisely controlled firing and 100 percent product inspection, these high-quality components are ideal for the most demanding of high-temperature environments.

Morgan Thermal Ceramics offers engineering and design expertise to support customers in the development of crucibles, tundishes, and launder systems. They will provide expert advice on material composition, pre-heat schedules, custom shapes and part installation, throughout the design and development process.

×