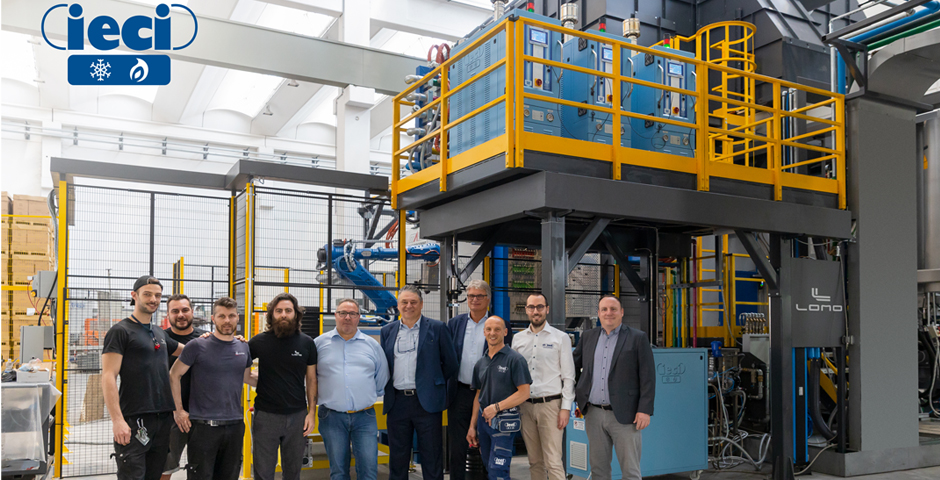

Together with IECI boss Mauro Inverardi and Federico Di Giovanni we were on the way to their customer Lomo (formerly Lomopress S.r.l.) in Monticelli near Brescia.

There, Lomo COO Felice Lo Monaco is already waiting for us, beaming with joy, because he is planning major investments and the new production hall is gradually filling up with brand new equipment.

The existing 17 die-casting cells are to be joined by 11 new ones. Three of them have already been installed and the trial run of the latest Maicopresse 3000 has started successfully.

Commissioning of the IECI temperature control system

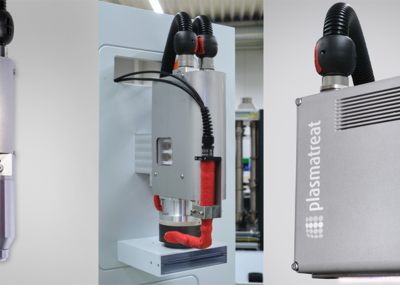

The complete temperature control system was supplied by IECI and runs on gas.

IECI is an internationally active, renowned company that celebrates its 50th anniversary this year and specializes in the manufacture of temperature control units for the plastics and metal industries. It holds numerous international patents and supplies customers all over the world with high-quality solutions for temperature control in dies, casting chambers and pistons.

Among the references of IECI customers are also manufacturers, who work with so-called giga or mega presses for the production of the largest die-cast parts that we know of. The control units for the giant presses can't be compared to the normal ones, says Mauro Inverardi. Everything is of course much bigger, the pipes are very different in size, number and diameter and have to be controlled at all points.

Lomo is a vertically positioned company

Lomo is well known as a die-casting foundry and, with approximately 300 employees, serves 70% of its customers in the automotive industry with large OEMs, but also other markets such as lighting, electronics and the renewable energy sector with very diverse components.

From this perspective, Lomo is broadly positioned and already works in an environmentally friendly way and attaches great importance to sustainability, conscious use of resources such as energy and water, as well as the reduction of CO2.

The long-standing cooperation with IECI, most recently with the gas-powered temperature control, is just one example of this.

We wish Lomo with Felice Lo Monaco and his team every success in the further expansion of the new hall and are looking forward to the next steps.

We will be happy to come back!