Meanwhile, it takes up to 14 weeks until a large and heavy transport of Siempelkamp Giesserei is approved by several federal states - providing the road infrastructure is compatible as well. According to the foundry, the application process via the nationwide portal VEMAGS (Procedural Management for Large and Heavy Transport) and the central coordination by Autobahn GmbH, in particular, cause additional and unnecessary delays in the planning and coordination processes.

"The introduction of the portal took more than 10 years and resulted in a system that has little to do with holistic digitalisation according to today's understanding," explains Siempelkamp Foundry Managing Director Dirk Howe and adds:

"Autobahn GmbH is growing to 13,000 employees, but is currently often overwhelmed with the fast and efficient coordination of route planning for important heavy transports. Applications that were processed in four to six weeks across the countries until 2021 and 2022, even in times of pandemic, now take weeks at Autobahn GmbH since the change in responsibility. And this happens without us, as applicants, being informed about the specific time when the approval will be granted, or being able to participate in the process in a supportive way".

The privatisation of the route monitoring that has been carried out additionally, aggravated the time problem, as there is a lack of so-called "cleared routes", trained drivers and vehicles in many places. "Because responsibilities for individual sections have to be clarified on five kilometres of a 500-kilometre route, our applications are additionally stuck in the offices," Howe states. Especially, the planning and booking of overseas transports of large machine components at the ports is almost impossible in practice under these circumstances.

Siempelkamp Foundry seeks alternatives for transport routes

In order to generate planning security for all parties involved, Siempelkamp Giesserei is increasingly shifting to other transport routes. Ship transport via the Rhine harbour in Krefeld plays a central role. The ports of Rotterdam and Antwerp are also more easily accessible for the Krefeld Foundry than domestic overseas ports due to simpler regulations in the neighbouring countries. "This naturally means that a lot of added value is lost in the German logistics sector and for our German overseas ports, which is a shame, but we cannot always take this into account," is how Howe explains the situation. Unfortunately, rail is currently hardly an alternative for these large components, despite a direct rail connection to the foundry site. "Unfortunately, there are hardly any trailers at the railway that are available for our transports weighing tonnes. In addition, the railways have drastically increased the prices for such transports and restricted flexibility. An ecologically sensible transport route thus becomes partly absurd under the given circumstances," Howe states.

Transport costs have risen rapidly on the road in a short period of time, also due to the privatisation of trackside services. In addition to the dynamic energy, infrastructure and skilled labour issues, additional bureaucracy is creating further locational disadvantages compared to better positioned European neighbouring countries. "One bureaucratic requirement chases the next. At the moment, even "trailing curve certificates" are required when applying for large-volume transports. The price per individual certificate is 350 euros," Howe states.

Foundry boss calls for more digitalisation in planning processes

While Siempelkamp Foundry, like many innovative medium-sized companies, has digitalised important areas of the company in recent years, public authorities are missing the opportunity to switch to digitalised solutions and useful AI tools for their own processes. "Many SMEs want route planning done at the touch of a button: What is the ideal route for the road train, what is the best time for it? It is difficult to understand why something like this does not work. Instead, several official bodies are involved in the process. Moreover, there is no recognisable perspective for improvement," Managing Director Howe states. The use of artificial intelligence in particular could help to reduce the workload for the authorities.

At the same time, some existing regulations should be adapted in the common interest. For example, heavy transports could not only run at night, but also at weekends, for example for the rapid construction and expansion of wind power plants. Also, return loads for standard transports, could be permitted without an additional permit in order to significantly increase the CO2 efficiency and thus the sustainability of the large vehicles. The Siempelkamp Foundry makes clear demands on the Ministry of Transport and Digital here: "The structures and processes must be improved as quickly as possible, otherwise the necessary transformation will not be realised on schedule. A balanced master plan is needed to rehabilitate the infrastructure so that east-west and north-south connections can be used without disruptions. If additional bureaucracy is created on top of the existing infrastructure problems, Germany's roads will eventually reach checkmate."

About Siempelkamp

Siempelkamp is a global group of companies with the business units Machinery and Plants, Casting Technology as well as Engineering and Service. Approximately 3,000 employees worldwide ensure that the Siempelkamp Group is represented with its technologies in the world's top league.

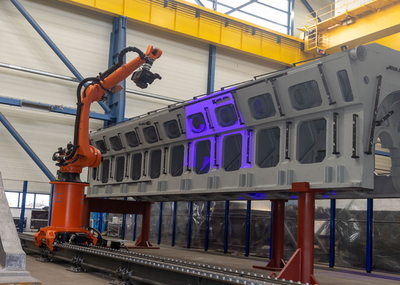

The Siempelkamp Foundry in Krefeld has specialised in the production of hand-formed large castings of up to 320 tons made of cast iron with nodular graphite. With a casting volume of over 60,000 tons per year and more than 400 employees, it is one of the largest hand-forming foundries in the world. The comprehensive and customer-oriented service package includes the entire production process from design, calculations, pattern making, moulding and casting to mechanical processing, packaging and transport.