The draft budget of the German government for the year 2024 provides for the cancellation of the reimbursement of up to 90 percent of the energy and electricity tax through a peak compensation for energy-intensive companies. The management of Siempelkamp Giesserei, world market leader for hand-molded castings, condemns this decision as an industry-damaging measure that will further impair Germany as a business location in the long term with regard to its already limited international competitiveness in terms of energy costs.

"There is still no viable concept for the imperative introduction of an industrial or transformation electricity price. At the same time, one of the few existing reliefs for energy-intensive companies is now being pocketed in order to apparently plug existing holes in the budget elsewhere. As a medium-sized company, we are now asking ourselves whether our production of components, which are proven to be central building blocks of the transformation, is still desired here," explains Dirk Howe, managing director and spokesman of Siempelkamp Giesserei.

The company, which manufactures many indispensable structural components for the energy generation, mechanical engineering, and automotive sectors, fears that the elimination of the tax relief will result in further significant additional costs in the future.

Politics has repeatedly broken promises - and is now additionally upsetting the industry

With an annual electrical energy demand of more than 50 gigawatt hours, the Siempelkamp Giesserei is one of the most energy-intensive companies in North Rhine-Westphalia. The electricity consumption corresponds to that of a small town with 20,000 inhabitants. The foundry already incurred additional costs in the millions as a result of the electricity price increases in the wake of the energy crisis. "Here, too, we had hoped for a clear signal from politics to counter this development - as in other European countries - be it through an industrial electricity price or a short-term adjustment of the merit order system. Neither has happened. Likewise, we may recall that there was a clear election promise by our current Chancellor to introduce an industrial electricity price of 4ct/kWh. Instead, the Parliamentary State Secretary Michael Kellner, as the SME representative, also promised that there would be retroactive aid for energy-intensive companies. This promise has not been kept either," Howe is upset. That 2024 now by the cancellation of the peak compensation a de facto tax increase comes also still to the medium-size industry, is for the industry experts from Krefeld completely incomprehensible.

Additional costs for customers and consumers alike plus declining competitiveness

It is well known that energy prices in Germany are high by international standards. The resulting higher cost of manufactured products ultimately leads to significant additional costs for consumers and further disadvantages for Germany as an industry location. "This means that there can be no sustainable fight against inflation and at the same time Germany is being damaged as a business location, which is losing more and more of its competitiveness," says Dirk Howe, summing up the unsatisfactory situation: "With the cancellation of the peak adjustment, energy is becoming even more expensive and the situation is thus becoming even worse - this really cannot be the aim of politics!

Proposal of pragmatic solution instead of bureaucratic subsidies

Siempelkamp Foundry has long called for an energy master plan that openly and honestly identifies the path of Germany's energy supply towards climate neutrality. "Currently, all companies that tackle the transformation from fossil fuels to electricity are punished with significantly higher costs, because electricity costs considerably more and the discontinuation of the peak compensation makes this situation even worse," the managing director of Siempelkamp Giesserei is irritated: "Therefore, an industrial electricity price, as it also applies in other EU countries, must help the companies to keep the currently expensive electricity prices predictable and competitive." In this context, Siempelkamp Foundry does not want any gifts at the expense of the taxpayers.

"The simple solution : An industrial electricity price can also balance out today's industrial electricity price with tomorrow's low electricity prices in the sense of interim financing. This means that the Government helps to finance today's additional electricity costs and receives the difference back when electricity prices are low in the future - a universal CfD (Contract for Difference) for energy-intensive industry - this creates security of planning on all sides, which is a basic prerequisite for the necessary investments," Dirk Howe is convinced.

Siempelkamp Giesserei as part of the solution

Siempelkamp Giesserei is determined to support the transformation of the energy-intensive industry in Germany and has invested large amounts in digitalization and process optimization in recent years in order to increase the sustainability of the company. "No foundry for hand-mold casting worldwide produces as sustainably as we do. No foundry specializing in such large and robust components has such a good carbon footprint. Without these components, there would be no electric vehicles, no raw materials for energy storage, and no production of climate-neutral steel. It is important that we, as an energy-intensive company, are not penalized for the fact that - due to the process - we need a lot of electricity for our investment in future technologies, we always refer to CO2 productivity in this context” , reminds the managing director Dirk Howe: "Especially when just three individual companies - Intel, Thyssen Krupp, Salzgitter AG - are being subsidized with almost 13 billion euros, one should consider how many hundreds of medium-sized companies with tens of thousands of employees could have been supported in their transformation with this amount of money. This would have made such an amount of money much more risk-diverse and more broadly supported by many innovative shoulders! It would be fair and sensible to invest a similar budget in the German SME sector to support the urgently needed transformation.

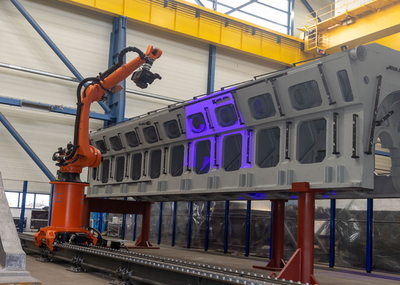

About Siempelkamp

Siempelkamp is a globally active group of companies with the business units Machinery and Plants, Casting Technology as well as Engineering and Service. Nearly 3,000 employees worldwide ensure that the Siempelkamp Group is represented with its technologies at the top of the world. The Siempelkamp Foundry in Krefeld specializes in the production of hand-moulded large castings of up to 320 tons made of cast iron with nodular graphite. With a casting volume of 50,000 tons per year and more than 400 employees, it is one of the largest hand-moulding foundries in the world. The comprehensive and customer-oriented service package includes the entire production process from design, calculations, pattern making, moulding and casting to machining, packaging and transport.