Traditionally, sand cores are used to create complex internal geometries in cast parts, such as those found in the automotive industry. These are often produced using the additive manufacturing process known as binder jetting. “The challenge,” Erhard explains, “is that we frequently encounter technical limitations when designing hollow structures in cast components. The trade-off between mechanical strength and removability of the core after casting significantly restricts our design possibilities.”

As part of her doctoral research at the Fraunhofer Institute for Foundry, Composite and Processing Technology IGCV, Erhard developed a novel approach. Instead of dry quartz sand, she uses a water-based ceramic slip with a consistency similar to that of liquid wall paint. The finer grain size and layer-by-layer application of the suspension allow for smoother surface finishes and higher density. Subsequent sintering makes the cores highly durable and heat-resistant – opening new possibilities for designing delicate internal structures in high-performance cast parts.

Intricate Structures for a Range of Industries

The method’s complexity matches its potential. Each layer must be dried before binder is applied, a step that significantly affects both material properties and process efficiency. Erhard focused intensely on this aspect: “Drying conditions are crucial for achieving flawless, homogeneous layer structures. With an optimized drying setup, I was able to produce a dense microstructure and reduce the average surface roughness depth by around 90 percent compared to conventional 3D-printed sand cores – down to just 1.2 micrometers.”

Removing the cores from finished castings posed another key challenge. “The more complex the core, the harder it is to extract after casting,” she explains. Her solution: built-in predetermined breaking points. These cause the core to fragment as the casting cools, allowing for easy removal.

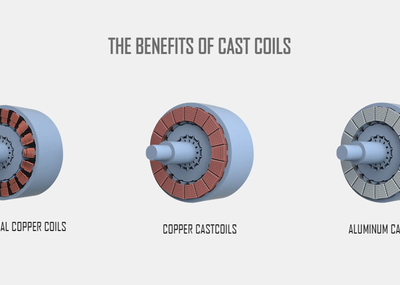

The advantages of slurry-based 3D printing are manifold: it enables thinner layers, denser and more stable cores, and greater design freedom. As a result, more precise cast parts with highly complex internal geometries become possible. Erhard validated her findings through two practical applications. First, she demonstrated that cooling structures in cast parts – such as those used in water-cooled electric motor housings – can now be produced with greater detail and efficiency. Her process allows for the creation of strong, heat-resistant cooling channels that direct heat away precisely where it is generated.

Second, she developed 3D-printed QR code inserts that can provide parts with a unique identifier throughout the entire manufacturing process – and potentially throughout their entire lifecycle. Beyond these use cases, the process developed by Patricia Erhard holds significant promise for applications in aerospace, advanced engineering, and the production of medical implants.

For this groundbreaking work, Patricia Erhard has been awarded the second place of the prestigious Hugo Geiger Prize.