Friedrichshafen. ZF presents the latest generation of electric drives for passenger cars and light commercial vehicles. It sets standards through outstanding power density and energy efficiency. energy efficiency. ZF achieves this thanks to numerous innovations at both the component and the system level. These include the the compact design of the drives, the so-called "discrete approach" to power electronics, and a resource-saving use of materials

materials, which also makes the production of the drives more sustainable. With their modular concept, the new ZF e-drives support car manufacturers flexibly and tailor-made in the further electrification of their entire model range.

further electrification of their entire model range. For the end customers, the new technologies offer greater efficiency, more power and shorter charging times.

ZF develops and produces technologies for the mobility of the future.Two million e-motors produced and the high-voltage vehicle electrical system with 800-volt technology, which will go into series production this year:

ZF is setting the pace in the dynamic electromobility market and is now is now further expanding its role as a technology and innovation leader. Proof of the company's successful transformation are the latest developments that ZF presented to the international media in Friedrichshafen on 21 November 2022.

System approach anticipates market requirements

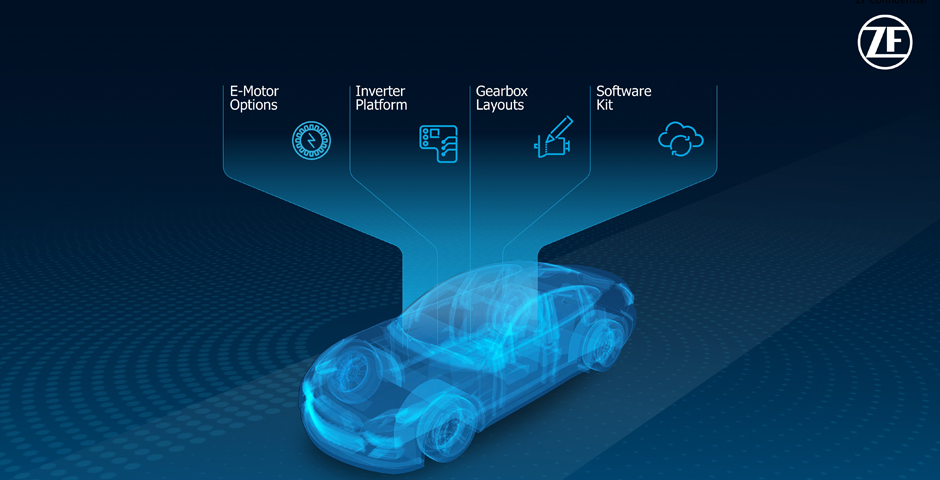

ZF is already developing its comprehensive product range for pure e-drives with a view to the functions desired by customers and end users. In order to better and faster meet the highly diversified market demand, the technology group is now presenting a new generation of electric drives based on a modular overall concept with electric motor, inverter, transmission and software. "We rely on three basic systems that almost perfectly fulfil the main requirements of our customers, namely efficiency, performance and costs, even in the standard version," explains Markus Schwabe, Product Line Manager Electrified Powertrain Systems. "On this basis, we can optimally implement further individual customer requirements in e-vehicles of all segments."

"The great interest of manufacturers in our products in both the passenger car and commercial vehicle sectors is impressively confirmed by our high order backlog in the high-voltage business. With the next generation of electric drives, we are consistently pursuing our strategy of developing sustainable and efficient mobility for the future ", explains ZF Board of Management member Stephan von Schuckmann, who is responsible for e-mobility in the Group.

Innovative strength in the system as well as in the components

ZF provides fully integrated electric drive systems with the new generation of e-drives. With its high level of interface expertise and unique know-how for driving strategies, ZF application engineers can optimally fulfil every customer requirement. However, the Group will also offer the innovative components individually, on which its own system solution is based. "Thanks to sophisticated internal interfaces, the new, extremely compact design allows system or component adaptations to be made with little effort. In addition, the design has a very high structural rigidity, which enables superior noise behaviour," explains Dr Otmar Scharrer, Head of Development for Electric Drive Technologies.

The new generation of ZF e-drives will be available on the market as a complete system from 2025. ZF will bring individual components into series production earlier. in series production. The following innovations at component level contribute contribute to the advanced overall system:

With the so-called "discrete package technology", the power electronics manage the balancing act between a high degree of component uniformity and high adaptability. The individualisation takes place at the chip level: a discretely constructed IF inverter is built with individual power semiconductor switches. This modularity offers better scalability of performance than is possible with complex power modules. In addition, ZF's "discrete package technology "requires fewer different types of components than when using conventional power modules. "With our new approach to power electronics, we can serve different market requirements faster and more precisely," explains Scharrer.

With a new, highly integrated e-motor, ZF has once again increased the power density compared to the technology currently available on the market. The decisive role here is played by a new cooling concept and a new winding technology. With the new cooling concept, ZF allows oil to flow directly around the copper rods - precisely at the point where most heat is generated during operation. Such highly efficient cooling significantly increases performance with the same weight and installation space. The continuous power of the electric motor is brought to 85 percent of the peak power. This also largely eliminates the use of heavy rare earths, making the production of the e-motor more sustainable. The braided winding technology developed by ZF, a further development of the so-called "hairpin" winding, enables a total of 10 percent less installation space. The winding head alone is around 50 percent smaller than with conventional approaches. This means that around 10 percent less raw material is processed.

With its new coaxial reduction gearbox, ZF is transferring its world-leading know-how in planetary gearboxes to the next generation of electric drives. Two planetary gearboxes integrated into each other not only generate the desired axle ratio, but also include the fully integrated differential function. Compared to conventional offset concepts, the new solution reduces weight and installation space requirements without compromising on efficiency, noise and vibration.

High-voltage converters (DC-DC converters) play a central role in fuel cell-powered electric drives. They compensate for the low output voltage and the sharp voltage drop when the fuel cells are under high load. The new high-voltage converter from the ZF power electronics platform, which was developed for passenger car and commercial vehicle applications, has a top value of 99.6 percent in terms of efficiency.