SP-HL pressure vessel conveyor, "THE ORIGINAL", a successful series from KLEIN Anlagenbau AG

- Well over 1000 conveyors in use (SP 25 and further development SP-HL)

- Continuous conveyor for bulk materials

- Small installation space, high conveyor capacity

- Gentle conveying and high energy efficiency through continuous conveying

Pneumatic conveying of bulk materials has many advantages compared to mechanical conveying methods, such as tube chain conveying or transport with conveyor belts.

Pneumatic conveying systems are clean and require little installation space and maintenance. Only the costs for generating the conveying air are disadvantageous. This makes it all the more important to exploit potential savings!

In a classic conveying process, the pressure vessel conveyor is pressurised with compressed air (ventilated) and the bulk material is conveyed through the conveyor lines, e. g. into a silo, by means of compressed air. For refilling, the conveyor and the entire conveyor line are completely deaerated, i. e. with each conveying process the entire conveying system is depressurised to ambient pressure and the conveying process is completely interrupted. With each new conveying process, any remaining bulk material in the conveyor line must be set in motion again.

Thanks to their design and their elaborate construction, the robust, worldwide used conveyors of the SP-HL series of KLEIN Anlagenbau AG enable an energy-saving, continuous conveying that is gentle on the bulk material and minimises wear on the system.

What exactly is the secret of the great success of the SP-HL series of KLEIN Anlagenbau AG?

The basic mode of operation can be outlined in a few words.

The details of the constructional design represent the comprehensive specific know-how of KLEIN Anlagenbau AG.

The core of the principle is a deliberately small pressure vessel in combination with a tight closing valve between the pressure vessel and the conveyor line. The small size of the pressure vessel results in a fast conveying cycle sequence, as only little time is needed for filling and delivery of the material into the conveyor line. As soon as the pressure in the conveyor line is exceeded during the ventilation process, the valve opens automatically and the bulk material is discharged from the pressure vessel into the conveyor line. As soon as the pressure vessel is emptied, the closing valve closes, the pressure vessel is vented and new bulk material flows into the pressure vessel. Owing to the closing valve, the pressure in the conveyor line is kept, and because of the short cycle time further bulk material enters the conveyor line after seconds. This way the low-wear and energetically favourable continuous conveying can deploy its economic advantages.

The pressure-litre product of the pressure vessel has deliberately been chosen so small that the periodic inspections of the pressure vessel can be carried out by "competent persons" within the company. Testing institutes such as the TÜV are not necessary here.

This also saves time and good money!

According to customer requirements, the SP-HL is available for different flow rates in DN 80, DN 100 and DN 125. For a maximum delivery rate, a tandem version for conveyor line diameters of DN 125 is available. In this case, two SP-HLs are delivering alternately into the same conveyor line in temporarily staggered sequence, thus contributing to further optimising the conveyor rate.

Figure 1 shows the comparison of conventional KLEIN conveyors with the SP-HL.

Figure 1: Conveying capacity of different conveyors depending on the conveying distance L*.

Figure 2 impressively shows the energy savings thanks to the continuous conveying with an SP-HL. Particularly for long conveying distances, energy savings of up to 50 % are achieved (energy consumption of a conventional T-conveyor in relation to the energy consumption of an SP-HL conveyor).

Figure 2: Compressor drive power of different conveyors depending on the conveying distance L*

The KLEIN SP-HL - Better buy "THE ORIGINAL" from KLEIN Anlagenbau AG –

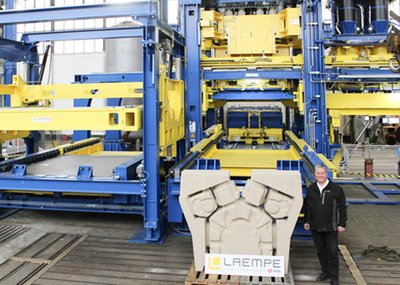

In the technical centre of the new building of KLEIN Anlagenbau AG, conveying distances up to 140 m can be realised immediately. Here, the most diverse bulk materials of our customers as well as different conveying methods are tested and optimised with the conveyors of KLEIN Anlagenbau AG.

Figure 3: New building of KLEIN Anlagenbau AG with technical centre

The KLEIN SP-HL - THE ORIGINAL

- unbeatable in energy efficiency and functionality -

- unrivalled in price and quality -