As an innovative developer of complete solutions, the long-established company Laempe offers a comprehensive portfolio of core shooters, gassing devices, sand mixers, sand preparation plants and core finishing solutions as well as networking and intelligent control for the entire core shop. The company implements automation solutions according to customer requirements up to the planning and realisation of a turnkey core shop. A comprehensive range of services in the areas of engineering, innovation and service round off the profile.

For almost 27 years, production has been carried out in Meitzendorf-Barleben, north of Magdeburg, while design work has been done in Schopfheim, and the staff around André Klimm is very busy, because high-quality mechanical engineering for foundries is booming and is finding markets all over the world, with a particularly high level of activity in North America at the moment. The global positioning of the company and the cooperation in the Sinto Group enable synergies and provide for a worldwide network.

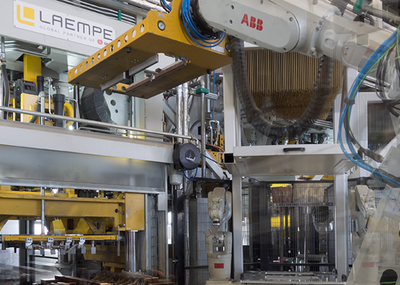

Our visit on site had a special occasion this time, because in the large halls at SKET GmbH (Schwermaschinenkombinat "Ernst Thälmann") in Magdeburg, the huge LHL200 - 1700 was set up for trial operation before it is shipped. In future, the machine will produce cores for the casting of ship engines in Weifang, China.

Henri Ackmann's team loves the big machine

The machine is so big that we had to move to the huge, historic halls of SKET GmbH in Magdeburg to set it up for the test run, Laempe team leader Henri Ackmann tells us proudly.

The huge construction made of iron, steel and a lot of technology impresses with its compactness and the imposing dimensions of 11m height, 16m length and 30m width with a weight of approx. 300t.

The sand cores can weigh up to 2,600kg with a maximum shot volume of 1,700l and a cycle of 6 cores per hour is possible. The machine can be operated by one person plus gripper, the mixer processes approx. 9t of sand per hour.

After the complete installation of the plant, Henri Ackmann's team also produced the first test cores and the results are impressive. They all worked perfectly, explains Ackmann to everyone's delight, and the cores are impressive. Rudolf Wintgens, Managing Director of Laempe Mössner Sinto, was also able to see this for himself and took the opportunity to emphasise the excellent cooperation of all departments at the Schopfheim, Mannheim and Meitzendorf-Barleben sites on this major project.

Laempe likes it big, no question about it, because Laempe's LHL200 is the largest core shooter built anywhere in the world to date, and it did so without an accident and with the passionate commitment of the entire team.

The Giga core shooter is now being disassembled again and sent on its journey to the customer in China via Hamburg. Those reponsible in Schopfheim and Barleben are convinced that the efficiency of the machine with its ability to shoot large cores in one piece will also be of interest to other foundries.

About Laempe Mössner Sinto GmbH

Laempe Mössner Sinto GmbH is the world market leader in core shooting machines for the and with its comprehensive product and service portfolio covers all areas of modern core areas of modern core production. The traditional German company is a complete solution developer with headquarters in Barleben/Meitzendorf, Saxony-Anhalt. At modern production site and in the branch offices in Schopfheim in the Black Forest and Black Forest and Mannheim, a total of 340 people are employed.