Introduction to our Company

KOVOLIS HEDVIKOV a. s. was founded as ironworks in 1816. In 1930, Polak’s patent for a cold chamber machine was purchased, and the company became the leading foundry in HPDC in the Czech Republic.

KOVOLIS HEDVIKOV a. s. is a family-owned, high-pressure die casting foundry of aluminium alloys with a long and rich history. It offers its customers complete solutions to their needs, including but not limited to the complex development of parts, design, and production of tools, production of castings, including mechanical machining, surfacing, subassembly, and welding if required.

The company currently employs over 800 workers. Thanks to their skill and hard work, it reaches an annual production level of over 12,000 metric tons and sales of over € 80 million.

The high level of automated production, usage of new technologies, and a sharp focus on the automotive industry help rank KOVOLIS HEDVIKOV a.s. among the most prominent foundries on the Czech and European markets.

Mainly Product Groups

KOVOLIS HEDVIKOV a.s. serves the following areas of the automotive industry: Powertrain, Brake Systems, Thermal Control, Turbo Chargers, Drive Systems, Brackets, AC compressors, Belt tensioners, Steering systems, and others. Seven different, both hypo and hypereutectic alloys, are melted in 10 melting furnaces with a total melting capacity of over 10 tons/hour. Casting runs on fully automated die casting cells with real-time shot-controlled casting machines, equipped by vacuum-assisted casting, jet cooling and squeeze, subsequent operations are also partially automated. The majority of castings are machined on a number of milling and turning machines, including special dedicated machines, and further proceeded by surface finish, sub-assembly, and welding (EBM and FSW).

Vision of Nowadays Industry

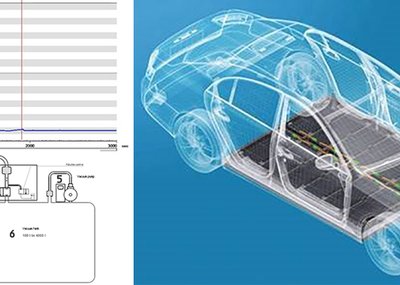

KOVOLIS HEDVIKOV a.s. tracks and follows the current trends in the automotive industry, offers their customers the parts with high complexity, reduced weight, improved functionality, and also special parts for hybrid and electric vehicles. Further development is forecasted as well. That is the reason why KOVOLIS HEDVIKOV a.s. introduced the semisolid casting, rheocasting method SEED, in 2013. Nowadays, it is beginning to use friction stir welding technology. As a point appreciated by our customers, we are able to fully develop parts just based on functional volume, including finite element calculations, prototypes manufacture and physical tests. Although KOVOLIS HEDVIKOV a.s produces a considerable amount of parts that are presented both in internal combustion engine vehicles and electric vehicles as well (e.g. AC compressors, steering systems …), the company is fully aware that projects for electromobility are important for the future, even though it is hard to say what the real share of electric vehicles in the following years will be.

Parts for independent heating have been in the company portfolio since 1996. In 2012, we started making prototypes of heat exchangers for electric independent heating for plug-in-hybrids and electric vehicles and went to serial production in 2015.

The Case Study

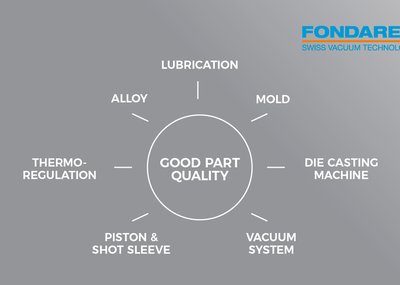

A heat exchanger is made of two castings welded together by electron beam welding. Welding is made both by butt weld and overlap weld. For good heating efficiency, the heat-transmitting surface must be of perfect surface quality without any flow mark, etc. Finally, the whole assembly is leak tested by helium high pressure. To combine excellent inner quality with a perfect surface, a standard vacuum system is not enough.

Why the choice of fondarex as partner for vacuum?

That is the reason why KOVOLIS HEDVIKOV a.s. has decided to use the Fondarex HighVac Premium machines for this product. The measurement showed a considerable increase of vacuum level in the die, which was confirmed by CT scans, cuts, and finally by welding results. Transmitting surface quality has increased, and the problems with flow marks and small blisters disappear. Moreover, the Fondarex HighVac Premium machine offers very good process control and parameter check for process stability and repeatability.