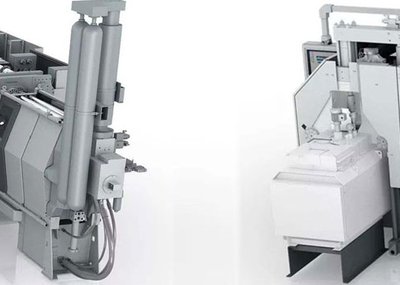

FRECH cold-chamber die casting machines with locking forces up to 44,000 kN

The Cold Chamber Die Casting Technology at FRECH guarantees a locking force from 1,300 kN to 44,000 kN with different process technologies: conventional / real-time controlled and Vacural®, while applicated with aluminum and magnesium.

Vacural Technology

The patented VACURAL process has proven its advantages for years in the production of castings with minimal gas and oxide inclusions. Due to the minimal amount of gas inclusions in components cast using the VACURAL process, the mechanical properties of the components can be influenced by heat treatment after the casting process in order to attain high degrees of stability under static and dynamic loads as well as elasticity.

After the introduction of Mr. Jürgen Lamparter (Executive Director Sales Cold Chamber Die Casting Machines), further program highlights included lectures about topics such as Oven-Technology by Mr. Roger Rapp (Meltec), Mold-Tempering by Mr. Norbert Obermaier (Robamat), Vacuum Processes, and Vacuum Insert in Die-Casting Technology by Mr. Martin Afkham (VDS)

It was an impressive sight for participants to see the GDK3200 in construction in the huge FRECH assembling halls in Plüderhausen. During the tour, participants busily networked and were able to better envision the different uses and needs for such machines in different countries.

Delegations from the near East and from the USA, on a shopping tour for FRECH machines and additional equipment, like ROBAMAT, MELTEC and VDS, were impressed by the entire tool technology, from dies up to 1200 x 1200mm, services, designs, measuring, and sampling, to simulations, trimming tools and FGS.

Customer Needs and Requests

In every process, FRECH customers are integrated. From engineering to product tools and machines, and the support with a special network, info exchange, suggestions, and tips and tricks. FRECH customer care and service provides maintenance, after-sales service through highly qualified and organized technicians with optimal calculated operating costs.