The foundry industry in India is booming. And Savelli Machinery India Pvt. Ltd., a company participated by Savelli Technologies S.r.l., ZETA, India, is running very well too. Recently, Gautam Casting Group (www.gautamcasting.com) announced the launch of the new plant at Rajkot, in presence of ONE Gautam Family. With a complete sand plant and return system as well as a new automatic horizontal flask molding line type F2, Savelli Machinery India Pvt. Ltd. was installed in this new foundry.

Gautam Casting has many Jolt squeeze lines in existing foundries but looking for a more modern molding process

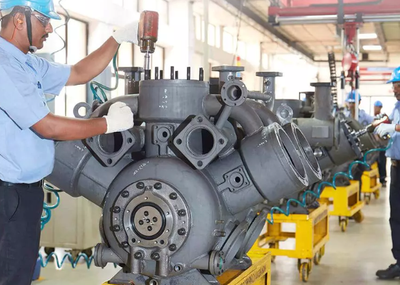

« Gautam Casting was looking for high pressure flask for medium speed production for producing tractor and earth moving equipment castings. After the evaluation of the molding processes, the team decided to go with SAVELLI high pressure multi-pistons squeezing solution. Because they have many Jolt squeeze lines in the existing foundries », so Anand Chebbi, Managing Director of Savelli Machinery India Pvt Ltd to the question of how this collaboration came about.

40 tones per hour capacity of Sand mixing for productivity of 60 molds per hour

The plant, which is currently being built up, is designed for 40 tones per hour capacity of Sand mixing for productivity of 60 molds per hour. The management team of the new plant in Rajkot is mixed of seasoned foundry professionals from the first generation and Technical Savy experienced from the second generation.

« We are proud that Savelli Machinery India Pvt. Ltd. was chosen when they moved out of conventional line to High pressure line «, so Chebbi.

The installation of flask line will open the gate for bigger size casting production

This step undoubtedly marks an important impact for Savelli. One reason for that is that Savelli Machinery India Pvt. Ltd. is a major player supporting Flaskless installation with sand plants and Cooling lines. Gautam group is a respected name in western area, and the installation of flask line will open the gate for bigger size casting production.

« We have another installation of Flask line coming in Gujarat, in Jamshedpur and in Mangalore. We are proud to mention that Lamina at Mangalore is a second line, under installation. The first line was delivered by Savelli Technologies S.r.l. and running for almost 10 years », Chebbi stated.

No major equipment supplier who can provide higher efficiency in sand plant

Concerning the development of the Indian sand plant industry, Chebbi confirms that there is actually no major equipment supplier who can provide higher efficiency in sand reclamation and recycling. In the opinion of Chebbi the Indian foundry industry is primarily driven by rapid industrialization and urbanization with a big focus in infrastructure projects. India stood as one of the world's leading countries in vehicle production. In the financial year 2023, the total vehicle production in India reached around 25.93 million units, marking an increase from the previous year, as reported by the Society of Indian Automobile Manufacturers (SIAM).

Savelli Machinery India Pvt. Ltd. made a breakthrough with SAVELLI F2 and F3 molding systems

Consequently, there is an escalated demand for car parts necessary for automobile manufacturing. To address this growing demand for metal castings in India, foundries are investing in new technology and equipment. Savelli Machinery India Pvt. Ltd., being a new entrant, made a breakthrough in this area with SAVELLI F2 and F3 molding systems (F1 technologies mainly from Savelli Technologies S.r.l.). As Chebbi states, the Indian Foundry Market size is expected to grow at a CAGR of 10.30% during the forecast period (2024-2029).