The idea arose in the course of digitalisation. Especially SMEs have difficulties with this issue, as digitisation and IT are very time-intensive and foundries often lack sufficient resources in this area. The number of manual work and process steps is still high, and efficiency potentials are not fully exploited. Fact is: digitalisation and AI are just at the beginning. In addition, there is a shortage of skilled personnel. Therefore, it was very important for Riedel to develop with the Pouring Ladle 4.0 a tool that improves efficiency, reduces waste, and offers - at the same time - direct added value to SMEs as well as to the single employee.

Significantly higher degree of reproducibility

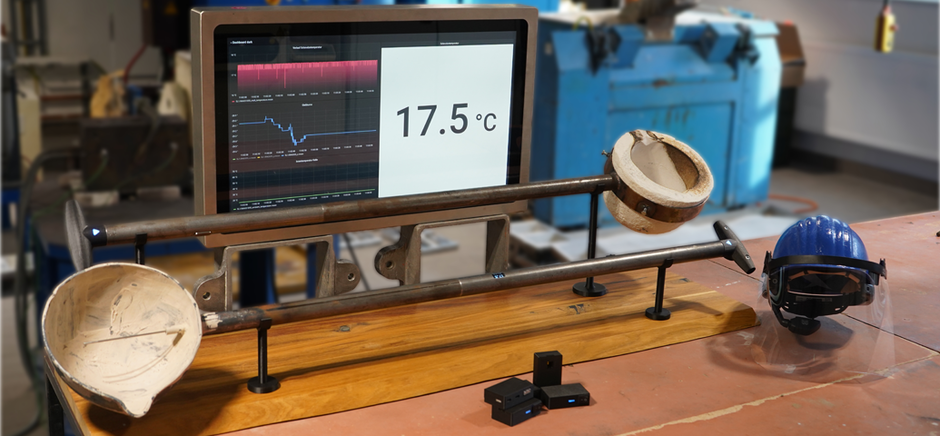

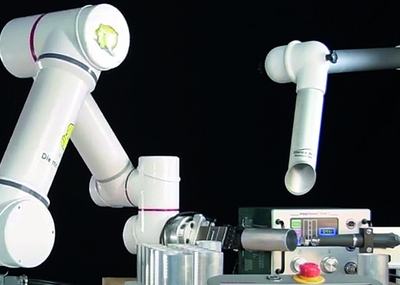

Through real-time recording and visualisation of process-relevant measurement data, as well as through the compatibility of the Pouring Ladle 4.0 with mobile end devices and data glasses, employees are actively involved in the digitalised casting process. A traffic light system in the process monitoring also offers the possibility of approval or, in the event of discrepancies, direct intervention. At the same time, the Pouring Ladle 4.0 has the same handling as the conventional model. However, from an economic point of view, the digitalised ladle offers numerous advantages. "We achieve a significantly higher degree of reproducibility and can thus actively avoid scrap," Riedel states. "The prototype is currently designed for light metals, but the technology behind could also be used for iron casting, for example." As a result, the Pouring Ladle 4.0 can basically be used in many foundries with manual casting production worldwide. Depending on the size of the company, the implementation takes only a few days.