|

The new PurEfficiency series of the well-known StrikoMelter® aluminium melting shaft furnace reduces energy consumption by yet another 10-15% without any modification to the installation height. In the benchmark test under real foundry conditions, an energy consumption of 525 kWh/t was measured for the first time in the new two-chamber melting and holding furnace MH II-T 3,000/1,500 PurEfficiency (melting capacity 1,500 kg/h), where this energy consumption includes after-heating for a constant pool temperature of 720°C. This efficiency gain was made possible by an integral examination of the furnace body, refractory lining and burner design.

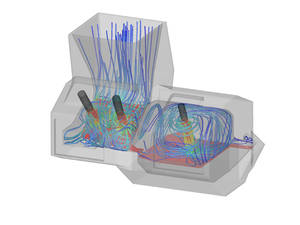

StrikoWestofen employs computation fluid dynamics to analyse heat transfer, optimize the burner arrangement and design the furnace geometry. Finite element methods are used to design the steel structure. In the PurEfficiency series, the furnace refractory was completely revised, with critical improvements in areas under high mechanical stress and in the insulator materials used. That means customers will not only enjoy considerable savings, but also longer service lives and lower repair costs. The PurEfficiency series is also available with melting rates of 1,500 to 3,500 kg/h and holding capacity from 3,000 to 6,000 kg, in stationary and tiltable design.

The entire StrikoMelter®-tower melter line is completed by dosing furnaces type Westomat®, crucibles for melting and/or holding, magnesium units as well as foundry accessories.

| StrikoWestofen GmbH is a leading supplier. For further information and contact details click here: StrikoWestofen GmbH |