The production site in Alabama has grown enormously in importance in the last 25 years, reports Christoph Dörr (European Office Director Alabama Department of Commerce) -- and the manager knows this from his own experience having spent several years there, even building a die-casting foundry.

The success story began in 1996 with the opening of the Mercedes plant, followed by Honda in 1999 and Hyundai in 2002, and Toyota-Mazda will soon be based there. With the four automobile manufacturers, Alabama is developing into the second largest production location for the automobile industry in the USA.

Mercedes is investing over $1 billion in its Alabama location, and the success story is currently continuing, Mercedes wants to build up the production of electric vehicles and build a battery plant where the elements of the new digitized production system MO 360 from Mercedes are to be used.

Success is appealing and attractive, so the automotive giants also brought with them many automotive suppliers to the state of Alabama. From Europe alone, around 250 companies have arrived in the area over the past 25 years, including around 80 from Germany and another 150 from Japan and South Korea.

In addition to the automotive industry, Alabama has around 300 aerospace companies, a second key industry with world-class companies such as Boeing, Lockheed Martin, GE Aviation, Raytheon, GKN Aerospace and Airbus. At Airbus, a second production line for the A220 has currently been put into operation, despite the Corona crisis.

The state of Alabama, located in the southeast of the USA, obviously offers foreign investors and companies not only a pleasant quality of life, but also an ideal environment, healthy structures and good foundations for research and development in the university sector. The most important institutions are Huntsville's Cummings Research Park (CRP), The University of Alabama (UA), Auburn University's National Center for Additive Manufacturing Excellence (NCAME) and University of Alabama (UAH) in Huntsville with the Marshall Space Flight Center of NASA.

This excellent mix has ensured rapid growth in the industries to this day, opened up attractive opportunities for expansion to companies from all over the world, and attracted interesting potential for new customers. And it ensured that companies in the supplier industry for automobile manufacturers and aerospace technology in particular settled here.

A completely new market has developed, especially for suppliers in the foundry industry such as mold making, automation, machine and plant construction.

International Die Casting Foundries in Alabama

BOCAR US, Huntsville - 2017

A new $ 115 million manufacturing facility in Alabama started in spring 2018. The 350,000-square-foot plant brings about 300 jobs to the area. The facility will be producing high-end structural aluminum parts for automakers operating in the United States

MAGNA KAMTEK, Birmingham - 2017

Kamtek's new $ 60 million manufacturing facility in Birmingham, a 150,000 square foot expansion of the auto supplier.

NEMAK, Sylacauga - 2000

Nemak Alabama represents the world's largest automotive engine block supplier. Nemak Alabama focuses its production on engine blocks and structural components for the most relevant OEMs worldwide.

2A USA, Auburn - 2010

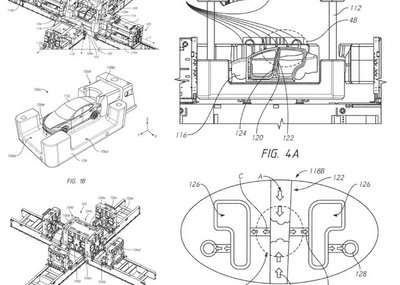

2A installed new equipment capable of exerting pressures on dies of between 1,000 and 2,700 tons, as well as 4,500 tons, representing the largest standard high-pressure die-casting machines on the market.

Shinhwa, Auburn - 2019

Invest $ 42 million and created 95 jobs in Auburn Alabama.

Source: www.madeinalabama.com