Fine new quartz sand is frequently used as a molding material, but other, significantly more expensive molding materials, such as synthetically produced cerabeads, are also used.

The end product—the cast parts to be manufactured—places various demands on the quality of the molding material. At the end of the printing process, the loose, free-flowing "Jobbox molding material" is transported out of the job box with suction devices. In many cases, it is sufficient to sieve the Jobbox molding material to remove coarse components, so it can then be reused in a high percentage for the manufacturing process of the next mold/core parts. A small percentage of the activator usually remains on the grain and is re-wetted with additional activator in the mixer before the 3D printer. Some cast parts with little or no tolerance for gas defects do not allow the use of previously used "Jobbox molding material."

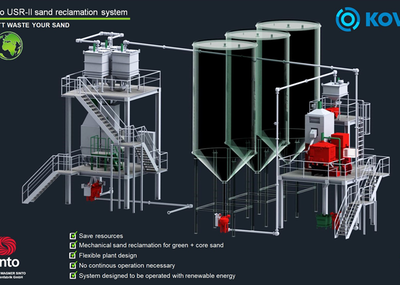

For such Jobbox molding materials, a reclamation plant was designed, developed, and commissioned for and with the highly innovative prototype and small series light metal foundry, Becker CAD, CAM, CAST (Becker CCC) in Steffenberg-Quotshausen. This plant largely removes the activator from the previously used Jobbox molding materials, making it reusable in nearly the same quality as new molding material. Ralf Dehnert, head of small series production at Becker CCC, set the task, precisely defined the necessary process parameters, and significantly influenced the process technology. Martin Dahlmann, responsible for special molding materials at Hüttenes Albertus (HA), contributed his knowledge of the synthetic molding material cerabeads used at Becker CCC, and G U T Giesserei Umwelt Technik GmbH handled the plant technology and concept.