Trendsetting: Reclamation of used sand secures the future of the foundry site

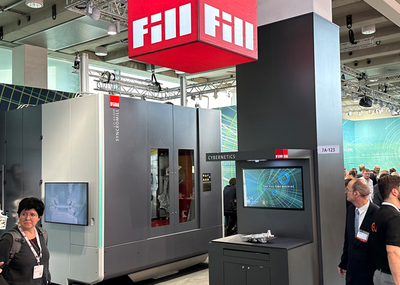

Heinrich Wagner Sinto Maschinenfabrik GmbH (HWS) is one of the leading international suppliers of machinery and equipment for the foundry industry and part of the Sintokogio group of companies with its headquarter in Japan. The company employs more than 300 skilled workers at its site at Bad Laasphe. The focus is on the manufacture and sale of moulding machines and moulding plants as well as pouring units for sand and die casting. The portfolio is supplemented by machines and plants for the mechanical reclamation of used sands in green sand foundries.

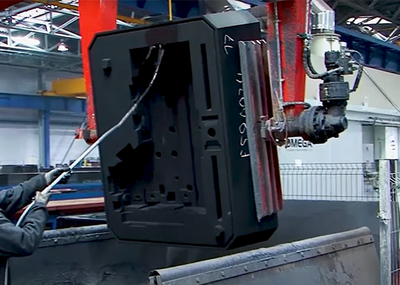

Mechanical reclamation by friction – USR-II

The HWS sand reclamation unit type USR-II (Ultra Sand Reclaimer) with a processing capacity up to 5 tonnes of used sand per hour with one unit, forms the heart of a HWS reclamation plant for green sand foundries. It provides efficient cleaning based on a friction process with high flexibility with regard to used sand composition and quantity. The process can be individually adjusted with a view to high reclaim yield (ratio of input quantity to output quantity) for both easy and demanding used sands to be reclaimed. An important feature is the gentle friction from grain to grain, without additional friction tools (see Fig. 1). This largely avoids grain breakage and keeps wear on the sand grain low.