Due to their focus on specialist applications, Otto Junker need to control all elements within the melt to very low limits. They had used several methods for process control, including a wavelength dispersive XRF and four combustion analyzers.

With a worldwide reputation for quality and a program of new grade development to support, the company needed reliable, easy to use equipment that would meet their ultra-low detection limits to ensure stringent control of melt chemistry.

So when we asked them to test our new OE750 spark spectrometer, they jumped at the chance.

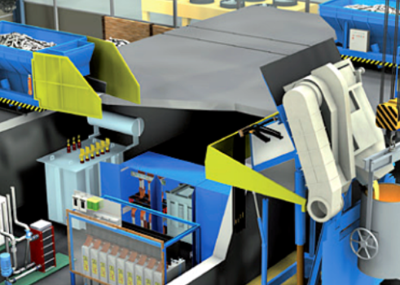

The OE750 is a next-generation, high-performance analyzer that delivers results that are usually only possible with far more expensive instruments. It covers the entire spectrum of elements in metal – depending on the application – and has very low detection limits, bringing high quality in-house analysis within reach for the first time for many foundries.

Read the full case study here.