- Risk minimization by updating to SIMATIC S7 control system

- Improved equipment availability and production

- Exploiting the full potential in equipment connectivity

- Ensuring service and support

Risks caused by old control systems and components

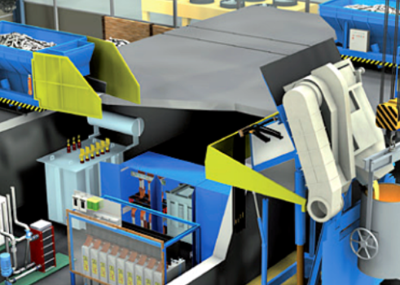

The production efficiency of foundry and thermoprocessing plants can be significantly increased by modernizations and modifications. One major aspect in this is the equipment control system.

OTTO JUNKER have launched a retrofit offensive in this regard and offer companies consulting services and the advantages of state-of-the-art equipment control systems. OTTO JUNKER have a lot of experience in this area and can look back at a huge number of successfully completed projects.

Last year, SACHSEN GUSS GmbH in Chemnitz/Germany successfully made the switch to S7 technology with assistance from OTTO JUNKER. The target was to carry out the modernization within the shortest downtime possible. This has been successfully achieved. What’s more: The customer can now take full advantage of the modernization.

„The main concern of the people in charge at SACHSEN GUSS GmbH was to obstruct the ongoing production as little as possible by the modification work. This was achieved by clever planning, close interaction and the preassembly of components etc.”

Jörg Neuhaus, Head of OTTO JUNKER GmbH Service Department