Boliden is one of the world’s leading producers of zinc, and the European leader in the production of copper and nickel. In addition, the company is a major actor in the recycling of electronic waste.

The new melting furnace system will be used in the production of granulated silver which is processed by the electrical and electronics industry to produce high-performance batteries or printed circuit boards for cell phones, to name but a few examples.

In support of the Paris Agreement, Boliden has set itself the goal to cut its CO2 intensity by 40% by 2030. To achieve this, significant investments are made to increase energy efficiency and reduce the use of fossil fuels.

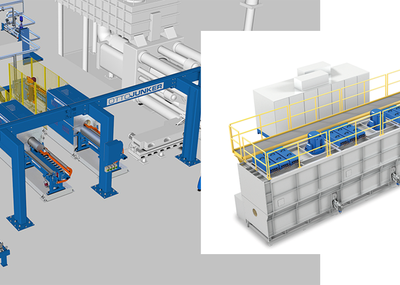

For this very reason the company has opted for an induction melting furnace with energy-saving coil by OTTO JUNKER, which is a future-proof technology which produces no environmentally detrimental emissions (CO2/NOx)

The system will be installed at Boliden’s site in Skelleftehamn and comprises a furnace with a 2500kg capacity and a frequency converter with a nominal output of 400 kW. It will offer a melting rate of 1520 kg/h.

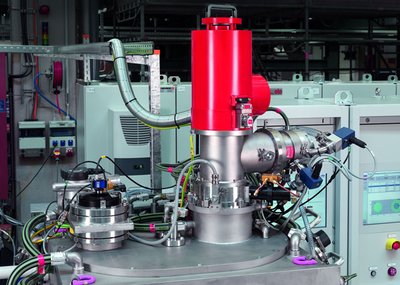

The frequency converter used is equipped with modern IGBT modules in order to operate the system with a consistently high power factor (cos phi = 0.99 at the converter input). This makes the system highly flexible and permits highly efficient operation at regular throughput rates.

The newly developed, PLC-controlled JuMI-Touch system will be implemented for automatic process control, monitoring and documentation. Special emphasis will be placed on automatic calculation of the requisite energy and its automatic input.

The complete equipment is easy to maintain, thus guaranteeing high availability, and impressively demonstrates the current state of the art of OTTO JUNKER process technology.