Last week we had the pleasure of visiting SIR ROBOTICS and were thrilled to see how versatile the company is.

We were able to get a personal impression of the company's authenticity and flexibility in a very short time, because the boss Davide Passoni and his team were open and receptive hosts.

Of course, we didn't miss the opportunity to ask Davide Passoni a few questions.

FP: Davide SIR ROBOTICS sounds at first like a pure robotics company, please tell us something about its history, status and direction.

The history of SIR Robotics starts in 1984, when it was founded in Modena, Italy by my father Mr. Luciano Passoni. He, who in those years was working in a mechanical design firm, had the intuition -brilliant for the time- to merge it together with an electrical engineering firm and a software firm. The combination of these skills led to a then innovative first creation: Tomcat, a six-axis anthropomorphic robot, as well as a range of Cartesian robots. So initially, SIR also manufactured its own robots that were used in the solutions offered to customers. At a later stage, however, it was decided that the robots would be purchased from companies that precisely industrialize them, to maintain SIR’s core business on their automation integration. SIR, in fact, still takes "naked" robots from other companies and customizes them specifically for each solution designed - that is, SIR works on all the non-standard parts around them. So, while initially SIR designed both robots and integration, today the focus is more efficiently on integration of robots for complete solutions: but it is because of those early design stages that SIR is fully aware of how robots work, unlike other integrators in the market.

In 1991, SITI B&T Group, a ceramic and sanitaryware technology provider based in Formigine, close to Modena, makes its entry and SIR begins to grow systematically until 2015, year in which the majority shareholder Mr. Tarozzi decides to close a deal with Wolong Group.

Currently, the worldwide leader of electric motors Wolong group, with its 20.000 employees, holds the majority shares along with other minor shareholders such as WAMGROUP. Wolong works for several prestigious brands in a wide range of applications, and has represented the turning point for SIR’s disruptive growth and internationalization in recent years.

Subsidiaries in the USA and Germany

Now SIR has a branch in Germany, another newly opened branch in the U.S. with four employees hired this year, and an affiliate in China that has reached 90 employees and works in the Chinese market, sometimes involving the Italian parent company for synergies.

The direction that SIR wants to take is precisely that of internationalization, promoting the export share, which has already risen from a minority to 70% of total sales in just a few years.

FP: As a classic special machinery supplier, you can be active in many areas. What are your main fields and in which markets can you find your customers?

The main industries in which SIR is active are automotive, both traditional and in the most recent electrical vehicles sector, and foundry. In particular, related solutions designed by SIR apply to processes on raw and semi-finished components, assembly, handling, welding and palletizing.

Alongside the two main fields, SIR also ranges in general industry, plastics and composites, and logistics to a lesser extent.

Regarding geographical areas, of course Italy has always been the historical market for SIR, however Europe and North America have been the region in which SIR has been most active in recent years.

FP: In which areas is SIR ROBOTICS used in foundries and are there examples of particularly interesting solutions?

SIR operates in both aluminum and cast iron foundries, offering customized and innovative robotics solutions by taking care of complex operations on heavy and bulky pieces.

Regarding aluminum processes, SIR is experienced on cutting, trimming and cleaning of castings, for example on brake pliers or other components, while regarding cast iron processes, on cutting, trimming, cleaning of castings and grinding on different types of components.

As far as handling is concerned in the aluminum foundry, SIR designs solutions for die-casting tending and also risers removal units.

In addition, SIR implements the preparation, bolding and assembly of complex cores with dedicated lines of up to 30 robots.

FP: At the moment we are talking everywhere about the advance of so-called GIGA or Megacastings, i.e. huge structural parts that replace many individual parts from one casting in die casting. Are your systems also used in this environment?

SIR systems represent the game changer in the context of the so-called jigs, as they automate their loading/unloading manipulation as well as all the entire subsequent process consisting of plasma cutting first and then deburring.

As a reference, we can detail for example an application recently developed by SIR for a major automotive customer in the market. The solution consists of a robotic line whose function is to perform the dematerialization of aluminum castings, particularly front and rear half-frames, using a plasma flashlight.

The system consists of handling robots that load and unload the components onto some process cells. In these, inside appropriate cabins, additional robots carry out the cutting and removal of sprues and sprue channels. The system is completed by manual deburring cells, which the customer plans to robotize soon. The main focus of the application lies in the use of technologies that enable clean cuts with far greater flexibility than traditional cutting solutions. The result is a line whose robots guarantee a high level of adaptability to the machining of parts of different shapes, keeping steady quality and very high efficiency, thus offering a viable solution to customers who are evaluating this new casting and frame machining process.

FP: The industry is currently facing major challenges. How do you see the future of your company, where do you want SIR ROBOTICS to be in five years' time?

Despite the difficulties given by the international situation, the robotics industry has achieved impressive results in the past year, both globally and locally. SIR also continues to grow, and the plan is to continue this trend.

In parallel with the creation of a new production department, SIR is building its new Italian headquarters, which will be ready in mid-2024 and will feature new modern spaces. Indeed, it is expected to expand both in terms of turnover (the projection is +50% in the next three years) and in the number of employees.

SIR’s peculiarity has always been the extraordinary flexibility to customize each of its designs. To have this impetuous growth, SIR will push patented modular solutions in the field of foundry processes, refining their features in order to present them to the market as quasi-standard solutions.

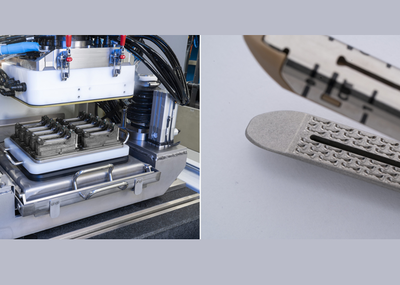

As an example, SIR sells MODULO, a universal machining unit, consisting of a structure rotating on an axis controlled by the anthropomorphic robot itself. It can accommodate 4 or more interchangeable and alternately positionable operating stations in the work area at the front of the anthropomorphic, and is offered in standard configurations for applications in the cast iron and aluminum industries. Combined with the use of appropriate Off-Line programming systems based on CAD or digitizer, the Modulo unit ensures perfect attainability of every machining profile, while keeping the quality of manufactured parts high and steady. Thanks to the new proprietary VistaVision® vision system, the robot picks up different types of elements without the need for any retooling, and the three-dimensional phasing of the elements achieves a rapid and functional final tuning of the paths generated in off-line mode.

FP: Where can your customers and interested parties meet you at trade fairs and congresses next year?

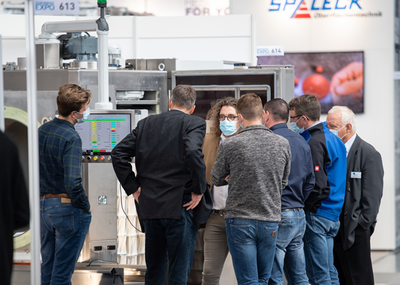

In Europe, SIR will be exhibitor at GIFA in June 2023 in Dusseldorf, Germany, and then again in Germany, Nurnberg, at Euroguss in January 2024.

In America, SIR Robotics Inc. will exhibit at following trade fairs and congresses:

- METALCASTING CONGRESS, April 2023 (USA, Ohio)

- MEXICO FOUNDRY CONGRESS, May 2023 (Mexico)

- FITMA, June 2023 (Mexico)

- THE ASSEMBLY SHOW, October 2023 (USA, Illinois)

Thank you for your hospitality, all the best and see you soon!