Michael Colditz, Duisburg/Germany; Seong-Heon Kang; Heung-Soo Kim, Pohang-Si/South Korea; Per Larsen, Copenhagen/Denmark

Each year brings new records in global vehicle sales. These do not apply equally to all parts of the world, however. New auto manufacturers are moving into the world market beside established names with a view to exporting from their home markets. And all auto manufacturers producing vehicles in other markets than their domestic market are expecting their suppliers to deliver locally.

Saturation in domestic markets has led to unused production capacity in industrialized countries. Prices are increasingly under pressure as competition grows. Auto manufacturers pass the consequences on to their suppliers, including foundries making automotive components. Thus especially manufacturers of brake discs and drums are forced to develop new strategies.

The extreme and constant pressure on the foundry industry is anything but new. It is remarkable how production is repeatedly scrutinized in detail and how efforts are made all the time to optimize every single process in the foundry. There are, however, some fundamental decisions that almost seem to have “religious” roots. Once a moulding process has been decided it is unshakeable. Truths and rumours about the various moulding processes vary and are often mixed together.

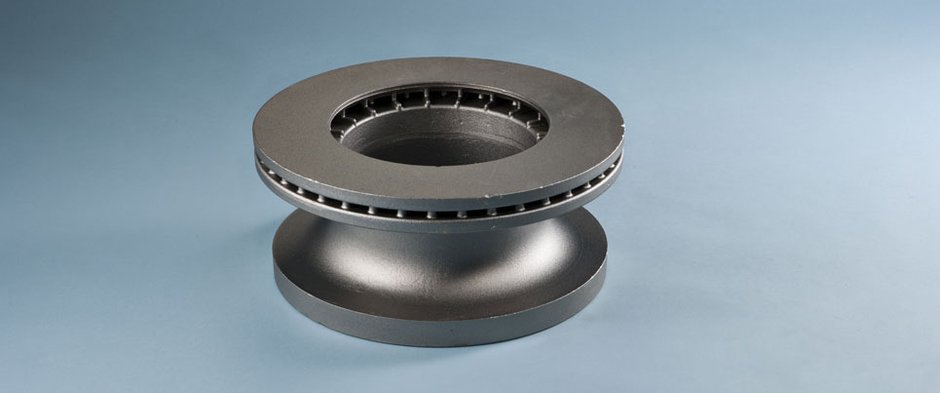

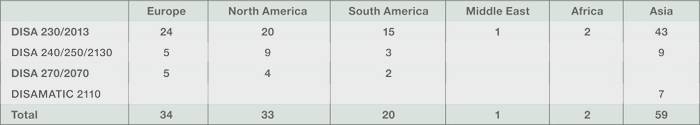

An extremely obscure aftermarket means that there are no detailed data about worldwide sales of brake discs. Based on our own market data as well as information from automotive system suppliers, it is estimated that about 6.5 million tons of brake disks are made every year worldwide. This output comes from vertical parted flaskless moulding lines, horizontal parted flask and flaskless moulding lines, and floor moulding. Currently 149 DISAMATIC- and 6 DISA MATCH moulding lines at 91 foundries are making their contribution. The share of world production of discs and brake drums on DISAMATIC lines is currently around 3.5 million tons per year (Figure 1). Table 1 below shows the DISAMATIC share of production of these castings.

Table 1: The moulding machine preference for brake disk production varies from continent to continent

Of the last 50 moulding lines commissioned for the production of brake discs, two thirds went to Asia, providing a clear sign of where the market is still growing. Investment costs and future operational costs carry most weight in new investment decisions.

Investment costs

Foundation costs are easily overlooked in the initial calculation, as plant supplier quotations do not include civil works. In many cases a simple foundation plate with a surface deviation of + / - 20 mm is sufficient for the vertical moulding process. The maximum deflection should not exceed 0.1 mm, as this could have an influence on the mismatch. As there is no need for pits below the moulding line, so the required maximum bending plays a subordinate role when installing on natural floor.

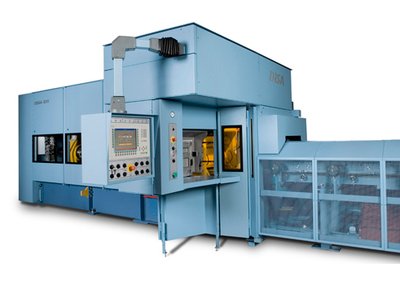

The simple and space-saving design of vertical moulding lines offers further cost advantages, some of which may only become apparent at second glance. The great advantage of vertical moulding technology comes from simultaneous moulding of the two mould halves into a sand mould and their immediate merging with the previous mould. This creates a very high production density on the foundry floor. This value is easy to quantify by examining the relationship between the annual production yield capacity and the area required for the moulding line plus service areas. The calculation of the underlying surfaces is shown in Figure 2. In addition to the surface area of the DISAMATIC moulding plant itself, service areas must also be taken into account. Moulding lines developed by DISA for the production of brake discs achieve an annual production yield capacity of more than 100 t/m2. Horizontally parted high-performance lines with two single or twin type moulding machines can only achieve about two thirds of this capacit, even when using multi-floor cooling houses.

Energy savings

The reduction of energy consumption in the foundry has played an important role for many years. Until now discussions have focused on reducing energy consumption in the melting shop where consumption is highest. While the moulding section may “only” account for about 8 to 12% of production [1], there is still a significant savings potential to be found. Moulding shop energy consumption is split between the sand plant and the moulding line. Depending on the type of moulding technology employed, the moulding line will account for between 30 and 55% of moulding shop energy consumption.

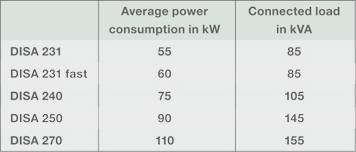

Systematic use of robust vertical moulding lines based on lightweight design criteria reduces energy consumption significantly (Table 2). Here, too, it is a good idea to address quantifying average annual consumption based on kWh per ton of yield. The drive for increased efficiency demands working in three shifts. Here we can set off annual production hours and actual energy consumption of the moulding line (moulding machine, core setter, as well as the pouring and cooling lines) against net production showing a definite potential for a consumption of less than 10 kWh / t. Given this result, the DISAMATIC vertical moulding process has nothing to fear when compared with other moulding processes and energy consumption is only about 20% of that of flask lines.

Table 2: electrical power consumption of DISAMATIC moulding lines

The production of brake discs and brake drums requires the highest possible capacity at low cost. The DISAMATIC moulding process fulfils these requirements more than any other. The machine construction is simple and requires at most only two drives: one for the moulding machine and the other for the pouring and cooling lines. Vertical parting of moulds enables placement of the gating system, as well as venting of the mould cavities, in the parting line. Other systems or sources of disturbance such as venting and drilling devices are not necessary. Production normally requires only one cooling line, thus eliminating the need for crossovers and the drives required by these as well. The absence of flasks means there is no need for mould punch out, thus simplifying separation from the greensand. Neither is there a need for recirculation and cleaning of pallets and flasks. The array of additional machines and tools required by tight flask lines mean higher investment costs, which in some cases can amount to the inves ment costs of a DISAMATIC line, and that must be taken into account when determining the cost per casting. The interference levels imposed by these machines and drives also point to higher uptime of vertical parted flaskless systems.

Ongoing service and spare parts costs vary from foundry to foundry, but can be roughly estimated to account for about 3% of annual investment costs based on external purchasing. While the percentage amount is likely to be similar for each process, the absolute cost burden is certainly not the same.

When considering investment costs, production intensity, resource consumption, uptime and maintenance are all clearly cost advantages for vertical moulding technology. Another area that is at least as important is the application technology that determines net production, castings quality and mould surface texture.

Application

One of the major benefits of the DISAMATIC is its high speed. On the other hand, high speed demands as very short mould pouring cycle time. The advantage of high speed combined with mould pouring required a correspondingly large-size gating system that reduced yield. Higher pouring speeds could be a reason for higher scrap rates. At GIFA 2011 a system was introduced that double indexed the mould string, thus extending the holding time by simultaneous pouring of two moulds. At the same time, several suppliers were offering pouring solutions that enabled foundries to make use of the advantages offered by the double index.

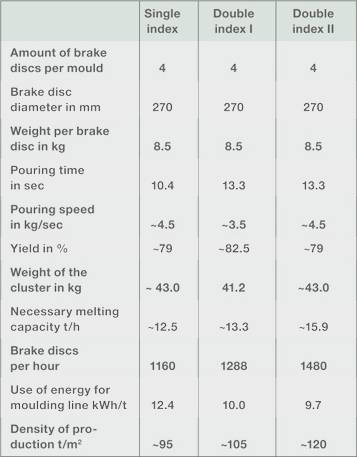

This development gives us an increase in performance that can be used in different ways. The longer pouring time can allow a reduction of the cross sections of the gating system, while freeing up space for additional castings or enabling improved cavity cutting. The longer holding time of the mould string and simultaneous pouring of two moulds can mean that pouring time limits the cycle time of the plant. Thus there is more time for additional moulds to be poured, resulting in a further reduction in the number of casting defects. In this way, a partial combination of the two advantages is possible. These advantages are shown in Table 3.

Table 3: Example of the performance increase of a DISA 270-A using the double index

Figure 3 shows the cluster forming the basis of the information in Table 3. The calculations for gating systems using a single index are similar to those for a double index. The differences lie in the

cross sections of the gating systems, which is however very difficult to see in the visual representation (Figure 3). By extending the pouring time using the double index from 10.4 to 13.3 seconds it was possible to reduce the pouring speed from 4.5 down to 3.5 kg/s. This meant among other things that the size of the pouring cup could be reduced from no. 5 to no. 4. The runner lengths and the cross sections of the gating system to the pattern could also be reduced. This enabled a 3.5% yield increase. At the same time, moulding capacity increased from 290 to 322 moulds per hour. However, pouring can also take place at 4.5 kg/s with a yield of 79%, thus increasing moulding capacity to 370 moulds per hour using double index.

Although the nature of the casting defects is fundamentally different in the production of brake discs using horizontal and vertical moulding processes, rejection rates are comparable. Microporosities occurring on vertical lines correspond to blowholes in horizontal lines. Any experienced foundry man is aware of these issues in the respective processes and knows how to rectify the problem.

There are no detectable differences after machining and mounting of brake discs in cars between the two production processes. A large globally active automotive company has confirmed that there are no qualitative differences in long-term operation between brakes discs made using a vertical or horizontal process.

A common disadvantage, especially of larger DISAMATIC moulding lines, is ferrostatic pressure arising during pouring of the mould. These vertical moulding lines with mould heights of 700 and 800 mm have been present in foundries since 1977. In 1979, the first DISAMATIC 2070-A commenced operation in a brake discs foundry with mould dimensions of 700 x 950 mm. Thus, we have 35 years of experience with issues and solutions. The effects of ferrostatic pressure can be handled via the gating system, but there are limits. Mould heights of more than 800 mm are not recommended for brake disc production by moulding machine suppliers.

Double-sided squeezing of sand moulds via the pattern plates ensures maximum hardness on the mould surface, which decreases somewhat towards the centre of the mould. Meeting this natural process advantage of the vertical moulding process in a horizontal flask process requires integration of secondary filling frames with the pattern bolster. Secondary filling frames are used to increase mould stability in the boundary areas of the flasks and to ensure the desired low draft angles.

In tight flask lines, closing devices are required to close the cope and drag, however with the risk of mismatch by mechanically determined clearance in the adjustments. Wear and tear of pins and bushings on all flasks must be continuously monitored. On the other hand, in vertical parted lines the finished mould will be pushed out of the mould chamber under the guidance of the pattern plate and placed in contact with the previous mould. This means that mismatch and consequent higher fettling requirements are significantly reduced.

In the vertical process, glued strips on the surface of the pattern plates ending at the top of the mould are sufficient for venting the mould cavity during the pouring process. Damage in the moulded cluster by subsequent piercing or drilling of vent holes is thus also eliminated.

Greensand

The choice of mould technology also has a decisive influence on the green sand circuit. In the horizontal process the amount of sand can be regulated to a limited extent by over-squeezing the cope. Iron-sand ratios in the range from 1:3 to 1:12 are not uncommon. Problems with recooling and equalizing the sand in the sand plant are correspondingly serious. The resulting quality problems will considerably impact the production result. Used green sand should be optimally prepared at a temperature of 40°C.

Vertically parted mould systems with their adjustable mould thickness prove to be advantageous in this respect. The PLC of vertical moulding lines assumes a constant iron-sand ratio. The foundry can, however, take advantage of the low pattern height in brake disc production to make adjustments according to its own needs. In this case, however, the above range is not reached. This constant ratio means that the thermal load on the mould sand is relatively uniform – an advantage for which any foundry quality department is grateful. Sand overflow that occurs in horizontal flask moulding equipment is practically non-existent in the vertical process, meaning that mould sand plants can be designed to be smaller, thus also reducing energy consumption.

Experiences of Hyundai Sungwoo Automotive in South Korea

The South Korean foundry Hyundai Sungwoo Automotive started production in May 1987 in Pohang / South Korea with a flask moulding system of dimensions 900 x 700 x250 / 250 mm. 410 employees work in an area of 60,000 square metres. The annual capacity of the foundry is 148,000 tons. In 2013, 121,000 tons of castings were produced, rising to 127,000 tons in 2014. The foundry produces automotive castings in GJL and GJS. The moulding machine was replaced in 2012, enabling a brake disc production cycle time of 15,2 seconds. In 2005, two DISA 240-C moulding machines with a mould size of 600 x 850 x 150 mm to 500 mm and a cycle time of 9.3 seconds were commissioned for brake disc production beside an additional flask moulding plant of the same size as the other with a cycle time of 20 seconds for other automotive castings. All plants producing brake discs are directly connected to cooling drums and continuous shot blast machines.

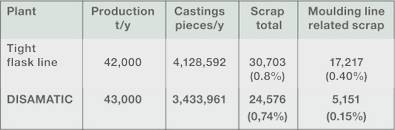

Similar production flow and about 4,500 hours production time at both plants in 2013 mean that the performance of the tight flask moulding plant and the older of the two DISA 240-C machines can be compared directly. Both systems make only brake discs, which however are distributed differently between the plants because of their dimensions.

The DISA 240-C features a rigid delivery system including a filter core for the transport of the cores to a core setting robot. Both the cores and the filter core are placed in fixed positions (Figures 4 and 5). Brake discs are manufactured in a range with diameters between 260 and 325 mm on the DISAMATIC in order to obtain acceptable system efficiency. The smaller discs, as well as a larger disc are made on the horizontal moulding line (pictures 7 and 8). The horizontal moulding line makes two large discs, or up to six small discs per mould box (Table 4), while the DISAMATIC always produces two discs per mould.

Table 4: Comparison of production on horizontal and vertical plant in 2013

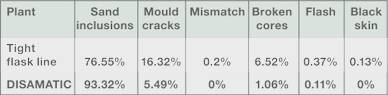

The scrap produced by each moulding line arises as a result of the following sources of failure (Table 5).

Table 5: Percentage distribution of the scrap of both moulding lines on basic of Table 4

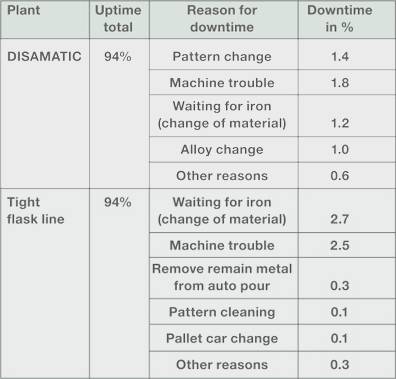

The percentage of scrap caused by the moulding lines, however, comes very close to the desired zero error-production. A comparison of the yield of each plant and its scrap rate invites a comparison of uptime. Again, the Hyundai Sungwoo foundry is able to provide accurate comparative data (Table 6).

Table 6: List of downtime

Due to the excellent management of the foundry, the production and maintenance departments guarantee a very high uptime on both plants. They employ a preventive maintenance strategy and educate their staff continuously promising further increases in uptime in the future.

Cast iron is used in both processes for patterns and pattern plates. Their expected service life in each process is 400,000 cycles before they are scrapped. The costs of these tools for comparable patterns vary considerably in the South Korean market. This means that the costs of core boxes producing the cores for the DISAMATIC moulding process amount to only 70% of those for comparable core boxes for the tight flask line. Prices of pattern and pattern plates for the vertical process are also more favourable, amounting to only 74% of those used on the tight flask line.

We lack detailed data in the area of mismatch and dimensional accuracy of the castings. There seem not to be significant differences between the two processes. 5mm are added to the diameter at all castings for machining, which is performed 100% in house enabling direct feedback in the event of quality issues.

The streamlined gating system developed by DISA enabled a significant optimization of the foundry in terms of yield. The total weight of a poured cluster of two discs using a conventional gating technology was 35.9 kg. The pouring cup and gating accounted for 12.9 kg, resulting in a yield of 64.7%. The introduction of new technology reduced the share of the pouring cup and the gating to 8.2 kg. The total weight of the poured cluster thus fell to 31.4 kg, increasing yield to 73.9%. The yield of the flask moulding plant is 73%.

A comparison of the power consumption by the two moulding machines is not possible in this foundry. There is however no doubt that the vertical moulding process has considerable advantages. It is, however, possible to compare the energy consumption of each production line including filter plants, vibration runners, sand supply units, belts and cooling drums. The energy consumption per hour of the tight flask production line is 625 kWh, while the DISAMATIC production line uses only 232 kWh. Neither figure includes power consumption by the heated pouring devices. Both systems have their own green sand preparation plant (120 t/h each) from different manufacturers. This is necessary because of the distances between the production lines and different demands on the greensand. In 2013, the power consumption of the vertical parted line sand plant averaged 530 kW/h, while the consumption of the horizontal parted line was 540 kW/h.

Summary

The article compares different aspects of brake disc production using vertically parted flaskless moulding lines and horizontal parted tight flask moulding lines. In the first section the vertical moulding process demonstrates advantages in terms of investment costs. The discussion addresses annual production density in tons per square meter of the foundry area in use. Area use is a significant factor in relation to production. Furthermore, annual energy consumption of the moulding lines in relation to castings produced is discussed, again demonstrating clear benefits from the DISAMATIC-technology. Developments in vertical mould process are tested for their effects on the application of technology. The possible increase in the yield or production volume suggests further potential for cost optimization in the foundry.

In the second section a comparison between two moulding technologies for the production of brake discs (Figure 9 and 10) is made on the basis of production data from the South Korean foundry Hyundai Sungwoo. The two plants have been in operation for several years, enabling us to learn from maintenance experience. Equipment performance as well as respective scrap and uptime were compared. In this case, no significant differences in performance, yield and quality between the technologies are found. The DISAMATIC moulding process, however, offers advantages in terms of tooling costs and energy consumption.

[1] Institute of Foundry Technology GmbH;

"energy-efficient foundry"

(Version 1.0) Dusseldorf 2008