When you never stayed in the middle of Jutland in Denmark before it is really exciting to meet so many friends, CEOs and engineers from leading foundries around the globe.

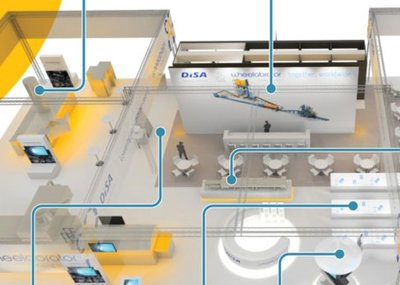

DISA arranged a convenient and also tough program starting from Holstebro with communication, lectures from DISA and a plant visit to one of the leading plants of the Skandinavian Casting Industry to Vald. Birn A/S where five DISA lines are actually running.

Peter Holm Larsen DISA President & COO) focused his welcome address with thank and respect to 104 customers coming from 26 different countries and almost 30 members of his DISA Team. Instantly they gained a familiar atmosphere for the entire trip from Holstebro to Copenhagen.

Between accessory lectures and the visit to DISA`s headquarters in Taastrup near Copenhagen there was the highlight of the visit to Vald. Birn A/S in Holstebro.

With a total of 650 employees, Vald. Birn A/S is one of Northern Europe’s largest foundry groups.

BIRN in Holstebro is the largest iron foundry in Denmark and together with its two subsidiary companies, Tasso A/S & Uldalls Jernstøberi A/S they accommodate more than 70% of the total cast iron produced in Denmark.

The parent company was founded in 1896 and today, the group includes also the following companies abroad: Vald. Birn GmbH (Mülheim, Germany) and Kockums Maskin AB (Kallinge, Sweden). Vald. Birn A/S is an international group with sales offices in the vicinity of their customers as well as sales teams specialised in meeting their customers’ requirements and demands.

The core competencies include all services from development, moulding, and machining to surface treatment and assembly.

Congrats to the Vals. Birn Group executives and guides who did a logistic feat in hosting so many experts in their facility and thank you for your self-confidence to invite the international guests. For sure the majority of all the visitors have taken a lot of knowledge, experience and the awareness that high quality production is possible with the right foundations, a propriate partners, skilled stuff and brave managers.

DISA Lectures:

Increase your production capacity: Bo Haugbolle

How to lower costs per casting: José Mintegui, Thomas Bloch

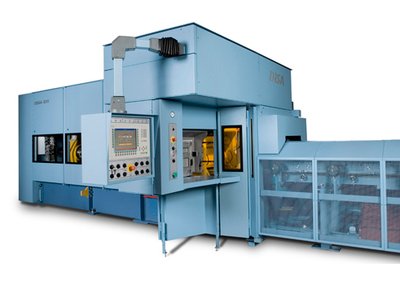

DISA MATCH Platform: Peter Harbo

Replacement of older DISAMATIC Equipment with a new DISAMATIC: Bo Haugbolle, Bernd Williams-Boock

Article: Thomas Fritsch, Editor in Chief

Foundry-planet.com