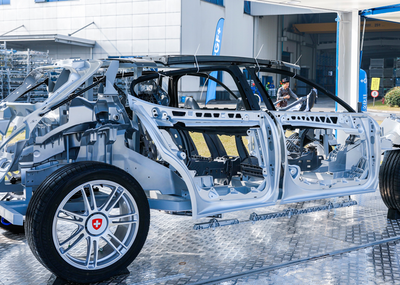

Die-casting components are getting bigger and bigger

The automotive casting industry is in transformation. Driven by advancing technology, components become bigger and bigger. Big castings offer numerous advantages, including cost and time savings in vehicle production, integration of functionality, and the reduction of overall vehicle weight. New vehicle architectures open doors for innovative ideas and even more development projects. These advancements create historical challenges for both car manufacturers and suppliers alike. To fully exploit these advantages, components need to be designed and developed with casting expertise from the very beginning.

Going beyond limits - Dimensions. Functionality. Performance.

Dimensions: GF Casting Solutions is constantly pushing the boundaries of what is possible, let it be the size of components or the limits of the equipment. By pushing the technical requirements in combination with the best product design, GF empowers its customers to find the most resource-efficient manufacturing process for each challenge.

Functionality: GF Casting Solutions stands for functional integration without compromises. Whether it is the connection to neighboring components or the integration of assembled parts.

Performance: Structural components, designed in close alignment with the customer, can show a better performance in stiffness and comfort.

Co-development and early involvement

For more than 25 years, GF Casting Solutions has been the pioneer in developing and manufacturing big structural die-casting components. Finding the right solution is not a one-way street. With its international R&D and in-house toolmaking capabilities, GF Casting Solutions is the co-development partner to simplify vehicle production - from design to industrialization. Being involved early in the development process guarantees the best results without compromises in dimensions, functionality, or performance.

GF Casting Solutions is one of the leading solution providers of lightweight components in the automotive and aerospace industry. As a future-oriented company, GF Casting Solutions leads R&D activities in early product development, supporting its global customers in their transformation – for a sustainable and resource-efficient mobility of tomorrow.