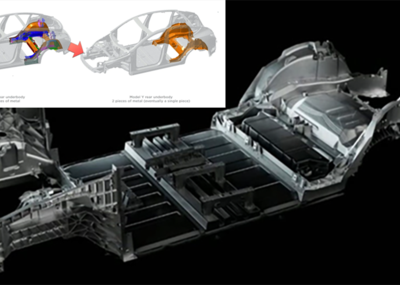

The company serves a multitude of industries including automotive, lawn & garden, transportation, and energy production.

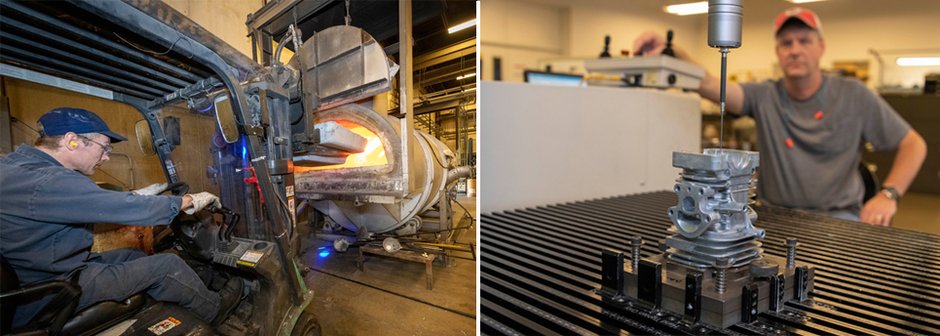

“General Die Casters has been successful by focusing on quality and investing in strong engineering controls,” states Brian Lennon, CEO/President. Long before a die is built, our engineering team works with our clients on both their requirements and the optimization for manufacturability. General Die Caster’s engineers, working with the latest software such as Magmasoft Flow Simulation, and real-time shot monitoring develop the greatest process control. We also offer CNC machining, addressing very tight tolerances. We can turn parts as large as 15” diameter and hold the tolerance to +/- .008 mm,.0003”. Our high-speed machining features 4 and 5 axis milling and 50” x 20” machine envelopes.

We pride ourselves on quality and use several tools such a Zeiss Coordinate Measuring machines, real-time x-ray, and Micro Vu Optical Comparators. We are ISO 9001:2015 registered and provide a commitment to, and demonstration of, confidence for our customers. GDC has also invested in robotic cells and cobots to maximize safety and efficiency in our manufacturing.

General Die Casters strives for continuous improvement as evidenced by our employee training program GDC University, which features an in-house program with over 60 videos on such topics as metal melting and handling, die cast machine operation, furnace cleaning, hydraulics, and process engineering. We also share our decades of knowledge with the world through our eBook the Die Casting Designer’s Handbook, offered for free on our website www.generaldie.com or by calling (330) 657-2300