Motivation:

- After RFQ received it may take up to a week or longer to establish a BOM + workplan + Manpower plan + Materials / Purchase Items availability + Machinery plan + Timings + many other Master Data!

- Scenario ideas and manufacturing routes are excluded in such preparation timing.

- Many assumptions / estimates prevail in metal casting operations!

- The work preparation department has a HUGE workload and may overlook items while establishing a robust pricing result!

Solution:

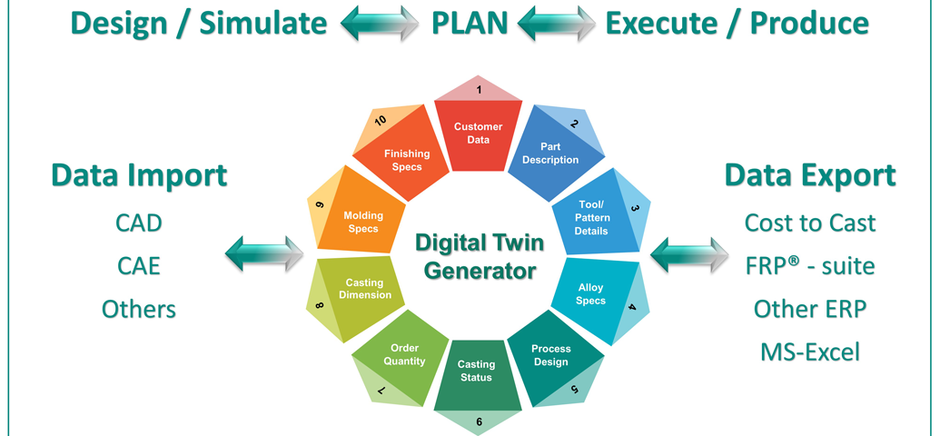

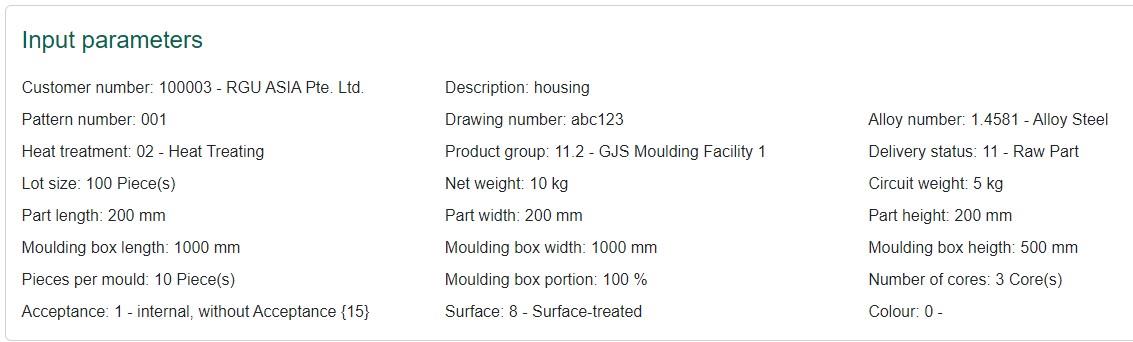

- FRP®.DTG can generate the complete digital twin (i.e. the FRP® - Resource Plan = BOM + Workplan + Manpower plan + Materials + Purchase Items + Machinery plan + Timings + any other Master Data) through a few easily accessible information fields (or even automatically obtained from CAD / simulation solutions) and data entry within MINUTES!

- The FRP®.DTG master data is upfront to be established by the FRP® team

- Manufacturing Scenarios can be easily utilised

- No assumptions / estimates (unless they are part of the master data and on purpose)

- Work preparation department workload reduced by up to 80%, a robust pricing is created to ensure profitability is always there, even IF unforeseen obstacles occur.

- The process is: èFast / èSecure / èTransparent.

As the basis for Foundry 4.0, it is mandatory to create an accurate digital image of the part and the involved manufacturing process. This is the foundation of all future activities. This must include all resources required for production. In addition, it maps the operational organization - the structural levels generate feedback points and respective storage information.