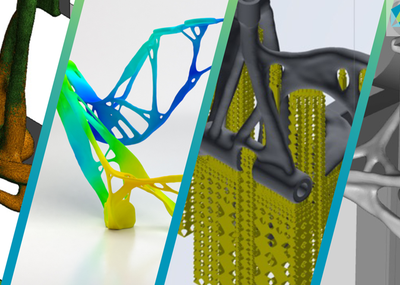

The ability to form metal or plastic components layer by layer means that complex shapes with tight tolerances can be easily produced rather than using a subtractive method where material is removed from a larger part like carving an item from a block.

Another benefit of additive manufacturing is that it’s easy and cheap to make a prototype. You don’t have to create specific tools or set up a costly production run, delivering less waste and better cost ratio for one-off or small-batch production. However, the move from prototyping tool to reliable manufacturing asset has thrown up several challenges for 3D printing, especially in the metal additive manufacturing sphere.

This guide provides insights on how to find an optimal solution for your additive manufacturing process quality control.

It covers in detail:

- Why is certification and chemical analysis crucial?

- OES – how does it work and how to perform offline measurements

- Oxygen as a process parameter

- Spectrometer requirements

- Example measurements of printed samples

- Case study: Samson

- How we can help with your samples

For more Information please click here