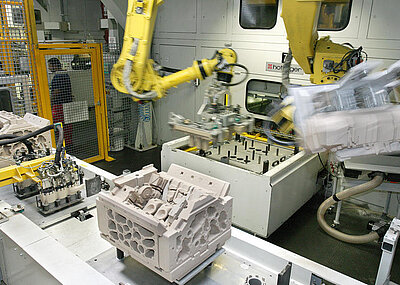

Nemak is a leading provider of innovative lightweight solutions for the global automotive industry, specializing in the development and manufacturing of aluminum components for powertrain and body structure applications. Headquartered in Monterrey, Mexico, the company employs more than 22,000 people at 38 facilities worldwide generating revenues of USD 4.7 billion in 2018. Nemak is a Tier 1 supplier to major OEMs and is among the world´s 60 largest automotive suppliers. The plant in Izmir, Turkey, produces oil sumps and brackets for leading automotive manufacturers in high pressure die casting as well as cylinder heads in gravity and now also in low pressure, supported by Kurtz foundry equipment.

Nemak, a world-renowned manufacturer of engine blocks and especially cylinder heads, has decided to further expand its production of cylinder heads. Due to a special design of the cylinder head, the ideal process in this case was not gravity as before, but low-pressure. Since greenfield construction was not possible at the Nemak Turkey production site, the capacity expansion was carried out as a brownfield project – this means existing halls were converted accordingly. The integration of the low-pressure process for cylinder heads took place quasi at the “open heart”: During ongoing production, the foundry was rebuilt and the new casting line prepared. Even for the assembly and commissioning of the first part in low pressure as a prelude to series production, ongoing production was not interrupted for a second.

Brownfield Project: a time and space challenge

This project was anything but standard for both Nemak and Kurtz. In addition to the extreme time pressure, the limited space available presented us with major challenges, which is typical for brownfield installations. Together, we ultimately came up with ideal solutions – a small excerpt from the implemented measures: Height reduction and adaptation of the cooling installation to the casting machines as well as adaptation of the overall layout of the FSC casting line.

Seven months to the first shot

The highest commandment was the adherence to the schedule. “We only had seven months from the award of the contract to the first shot, which is absolutely unusual for such complex projects. Such a goal can only be achieved if both sides are passionate and give their all. The cooperation during the project and planning phase, the assembly time on site, where everything ran hand in hand, up to commissioning, was simply super,” says Lothar Hartmann, General Manager Business Unit Foundry Machines Kurtz GmbH, looking back on the extremely ambitious project. This was the only possible way to meet the time schedule despite the one or other small hurdle.

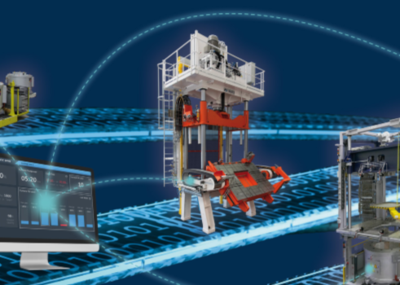

On technology: Nemak opted for a Kurtz casting line AL18-16FSC. The highlight of the line is the cooling technology with 48 regulated water circuits, which can later be extended to 96 circuits if required. Cooling is controlled by temperature and time. Thanks to the large low-pressure casting furnace with 2,800 kg aluminium capacity and the additional machine equipment, Nemak can produce frames and structural parts as well as cylinder heads in two cavities. In the final stage, the casting line will consist of a total of four machines and will be completely installed by June 2020. “With the Kurtz AL18-16FSC, Nemak is well equipped for future castings – both for light-weight construction and e-mobility. We would like to take this opportunity to express our sincere thanks for this extraordinary cooperation – a cooperation you can only wish for. All the best for Nemak and good luck for the future,” stated Kurtz Managing Director Uwe Rothaug.