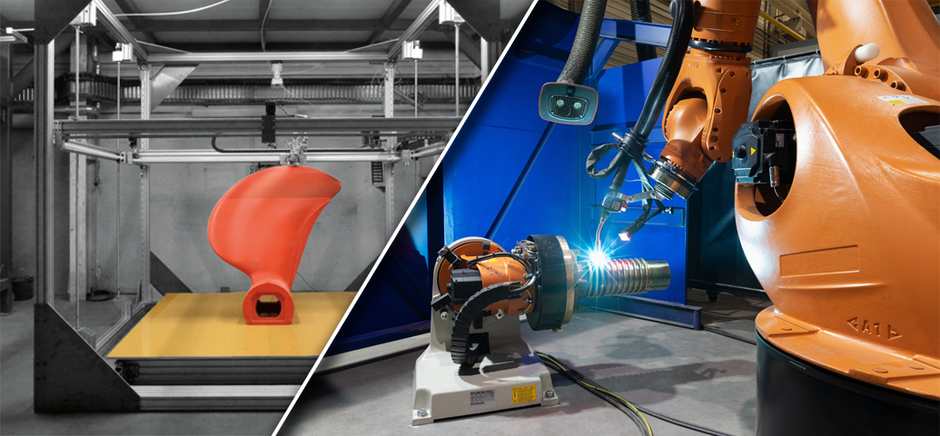

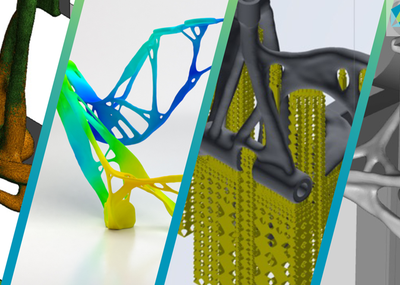

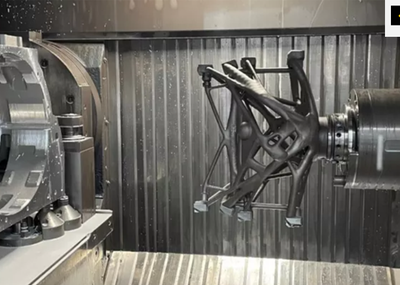

Thus, in addition to sand and centrifugal casting, additive manufacturing with an automated welding robot and an XXL plastic printer have been implemented. For example, a hybrid robot-assisted production process consisting of additive and subtractive manufacturing was used to produce a drinking fountain, which allows the component to grow in an automated and targeted manner. Due to the low energy input in the CMT process, complex and large-format component geometries can also be implemented. Different strategies in thin-walled as well as thick-walled areas are a prerequisite for optimized component generation. With regard to cost and resource efficiency, the technology opened up many potentials compared to conventional manufacturing methods - in particular the drastic shortening of manufacturing and product development cycles as well as the reduction of the necessary material input.

Come and visit Mecklenburger Metallguss GmbH (MMG) at the Fromnext 2023 at Hall 11 E68