The optimisation of complete systems in mould spraying for die casting moulds is crucial to ensure efficient and high-quality production.

A pronounced specialist on the subject of mould spraying is the company GERLIEVA, which has made a name for itself for years through high vertical integration, individual solutions and customer support.

We spoke to the experts at GERLIEVA and summarised the most important approaches for the continuous optimisation of the spraying process as follows:

- Select the right release agent with special attention to environmental aspects and safety standards.

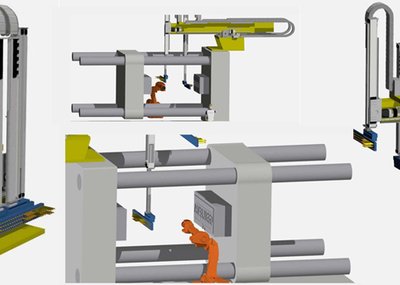

- Use automated spray systems to ensure uniform and consistent coating of the moulds.

- Implement sensors for monitoring and control, from release agent quantity detection to spray circuit and single nozzle.

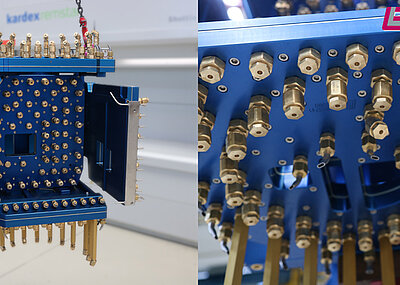

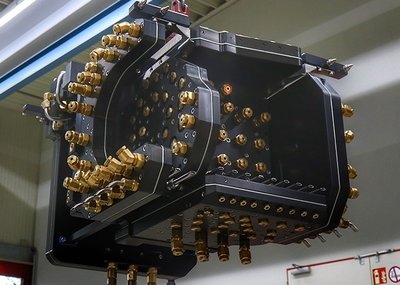

- Optimisation of spray technology starts with customized sprayheads, efficient use in release agent consumption to the correct spray angle, spray pressure and spray speed. The best results are achieved with customized sprayheads.

- When it comes to maintenance and cleaning, GERLIEVA offers preventive measures. Regular maintenance schedules, which can also be carried out on site, can ensure that the spray systems function properly and that deposits and contamination do not cause any impairment.

- Training and qualification for the appropriate use of the systems is naturally part of the offer of a full-service provider like GERLIEVA. The training courses cover everything from proper handling to programming the spraying and maintenance programmes.

- Data collection and analysis: The full-range supplier also offers its support in this increasingly important point when it comes to collecting and evaluating data in the spraying process. The aim of suitable analysis tools is basically to identify potential for improvement and to recognise trends and patterns at an early stage.

The optimal mould spraying process for die casting moulds requires a combination of technical know-how, automation and continuous improvement.

A full-range supplier such as GERLIEVA covers all the essential components and this leads, in the sum of the implemented measures, to more efficiency and higher product quality at calculable costs.

Vist GERLIEVA Sprühtechnik GmbH at Euroguss 2024 in Hall 7 / Booth 7-234