On June 12th, the 15th International Foundry Fair (GIFA) in Düsseldorf will open its doors together with the THERMPROCESS, METEC and NEWCAST fairs. Several key players from the „Bright World of Metal“ will be on site in order to present innovative systems - this year will be characterized by the requirements to sustainable developments. The OTTO JUNKER and INDUGA furnace specialists will be there, of course, to present their solutions in the induction melting and thermoprocessing equipment fields. Visitors to the fair are invited to come to booth F57 in hall 10 and have interesting technical discussions with our team of experts.

Main topics:

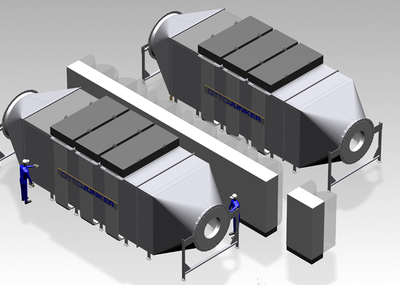

- High performance melting furnace plants

- CO2 free inductive melting

- Safety and availability (IGBT, OCP+)

- Energy saving & recycling

- Automated pouring

- Service and OTTO JUNKER Academy

- Research and development

Erik Míček, OTTO JUNKER CEO, says: „For OTTO JUNKER, the GIFA/THERMPROCESS is the most important trade fair and an important opportunity to exchange ideas with our customers with regard to our equipment and product developments as well as the market situation”. Energy efficiency and saving, and thus the recycling process, play a key role in this, irrespective of the application.

The route to less CO2 and more resources

The below developments will be shown by means of exhibits and visualizations and, above all, in individual discussions:

- Induction melting plants which do not emit CO2 during production replacing cupola furnaces and gas-fired furnaces

- Possibilities of heat recovery and the use of power from additional photovoltaic systems

- Reduction of energy consumption of a melting furnace by means of modern equipment technology, charging and mode of operation

- Suitability of the induction furnace for recycling processes due to its precisely adjustable bath movement

- Examples of application, also in connection with a pyrolysis oven for organically contaminated scrap

Planning, observation and safety

During the fair, OTTO JUNKER shall present a new learning module of the OTTO JUNKER Academy: The use of virtual reality glasses for simulating critical operating conditions in a foundry environment. That way, operating and maintenance personnel can be trained to be prepared for potential emergencies in an understandable and clear manner under realistic circumstances. The virtual environment allows the workers to learn the correct behavior on the melting furnace under critical conditions.

Another advantage for the working processes is shown by means of the IGBT converter technology. On the one hand, this technology offers optimum operational safety due to disconnectable elements, on the other hand, you can continue to run the plant with slightly reduced power, even if an IGBT fails.

OTTO JUNKER have continued to develop the well-proven laser-optical measuring system for monitoring crucible wear and the thermal load on the induction coil and have made the operator interface more user-friendly. During the fair, OTTO JUNKER will also provide information on the OCP+ (Optical Coil Protection) system.

Learn, act, transform

OTTO JUNKER offer a wide range of products in the thermoprocessing equipment field. Experts will be available on our booth to give advice and exchange ideas on high convection heating, gas-fired heating, electrical heating, induction heating, heat recovery and recycling technology.

Further to that, experts from our Service and R & D departments will answer questions asked by fair visitors. For example, the Service department will inform you about maintenance and modernization options of existing plants. R & D will present new developments in pyrolysis and battery recycling as well as in the sustainable heat and energy storage field covering all sectors.

In this connection, the new power-to-heat module for producing hot air of up to 1,100 °C for loading an energy store will be presented. The development of the module as part of the multiTESS project together with Solar-Institut Jülich of the Aachen Polytechnic (SIJ) and in cooperation with industrial partners last year was a milestone which will open new doors for OTTO JUNKER in the high temperature heat storage and electrification fields.

The industry is in the middle of a transformation of the energy and recycling sectors. OTTO JUNKER and INDUGA are well prepared to make their contribution for the development towards a green market economy and look forward to welcoming many interested visitors and holding exciting discussions on new and existing furnace plants, technologies, processes and applications in the foundry and semifinished products industry.