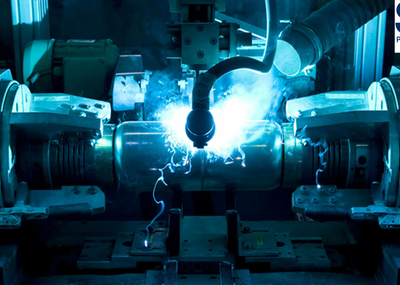

The special casting process in which aluminum is cast in a semi-solid or semi-liquid state, so-called rheocasting, seems to be in vogue at the moment and there are good reasons for this.

Only recently at the Aalen Foundry Colloquium we met Fabian Hofstätter from Salzburger Aluminium AG (SAG), who gave an interesting talk on the subject.

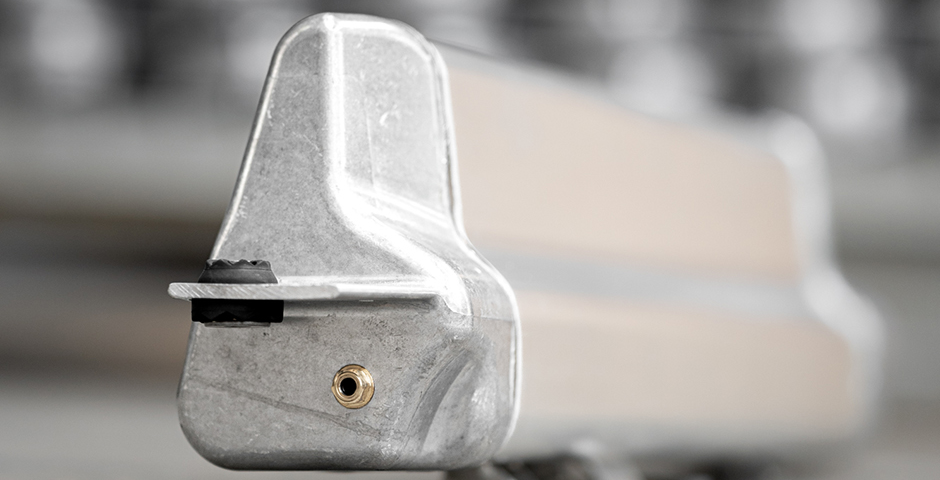

We are particularly interested in the advantages of the process and which components are specifically suitable.

With regard to the advantages of rheocasting, several major focal points immediately stand out, which are of utmost importance for aluminum components.