Vibratory finishing system utilizes customer’s existing material handling & drying equipment

When it comes to high volume production of complex aluminum die-castings, Kovolis Hedvikov a.s. is a sought after partner by numerous car manufacturers and their suppliers. To expand its capacity and achieve more flexibility in the overall manufacturing process this company purchased a new vibratory finishing system that can handle a wide work piece spectrum and was custom engineered to fit into the available space at the customer’s premises.

The die-casting company Kovolis Hedvikov a.s., founded in 1816 as an ironworking operation, has a long and eventful history. Since 1945 the company focus has been entirely on aluminum die-casting. Today, Kovolis produces components from nine different aluminum alloys weighing between 200 grams (7 ounces) and 8 kg (18 lbs.) with different casting technologies like vacuum investment casting and rheocasting. Their product range includes brakes, power steering systems, turbo chargers and compressors for air conditioning systems. Their customers are renowned car manufacturers and tier-1 suppliers who also employ Kovolis as an important partner for product development. In addition, the company provides services for machining, heat treatment and surface finishing.

Fast and gentle surface finishing

Jiri Buzek, manager of foundry III at Kovolis, explains the need for a new vibratory finishing system as follows: “Our product portfolio underwent a drastic change in the past years. The trend goes more and more to larger and more delicate components, which require a vibratory finishing step after punch deburring for their downstream handling. Our existing finishing system was not designed for this and had also reached the end of its productive service life.” The new system had not only to cope with larger work pieces, but the finishing process also had to be a lot gentler. Additional customer requirements were high equipment uptimes and cost efficiency. And, above all else, the new finishing system had to be integrated into the existing manufacturing operation, utilizing the existing work piece loading device and hot air belt drier.

The planning engineers at Kovolis submitted these specifications to two German equipment suppliers. The foundry manager continues: “We decided to go with the Rösler continuous feed vibratory finishing system, because it offers ample capacity, and Rösler met all our special technical requirements. Of course, the fact that our company has had excellent experience with other equipment from the same supplier certainly helped.” Important was also that besides the equipment Rösler can also supply all compounds and finishing media the customer needs. This allows the perfect adaptation of the finishing process to the customer’s work pieces.

Fully automatic feeding of the work pieces every 30 seconds

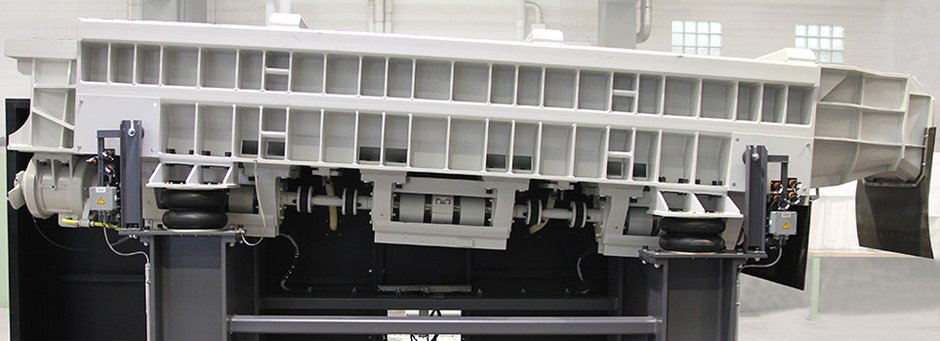

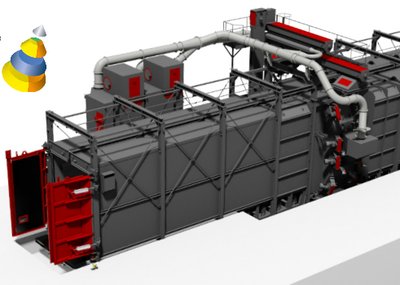

The new finishing system consists of a linear continuous feed machine, type R 550/4600 DA, with a usable length of 4.6 meters (15 feet). The functions of the existing work piece loading system and hot air belt drier were integrated into the overall system controls. „Rösler met all our technical requirements and provided valuable support in optimizing our finishing process,” explains Mr. Buzek.

About 30 different work pieces with a maximum diameter of 300 mm (12 inches) are currently processed in the R 550/4600 DA. Since it can handle parts with diameters of up to 400 mm (16 inches), this machine offers a high degree of flexibility for the future. Moreover, the system for automatic work piece loading can be easily adapted to a new work piece loading system, which may be installed later on. Depending on their individual design the castings are fed into the finishing system at cycle times between 30 and 60 seconds. The single curve U-shaped cross section of the processing channel guarantees the optimum movement of the media and work pieces through the machine. This unique design and the use of high performance plastic media, type RKM, produces perfect finishing results within a maximum processing time of eight minutes. The processing time can be adjusted by simple inclination of the processing bowl. Compared to systems with a separate vibratory discharge channel the work pieces are travelling through the machine at a constant speed. This prevents any jams, which could cause nicking or, even, deformation of the work pieces.

Dual stage separation with rinsing station

To prevent any damage to the delicate work pieces during the separation cycle, the multi-deck vibratory screening unit contains two steps with minimal drop heights. The undersize media classification system is equipped with an adjustable bar screen, which allows Kovolis to decide at which dimensions undersize media must be discharged.

Since the finished die-castings do not undergo a separate cleaning step for removal of media fines from their surface, the separation unit is equipped with a spray-rinse station. After the work pieces have passed through the hot air belt drier, they go straight to packaging or machining.

Cleaning of the process water with an automatic centrifuge

In addition to the R 550/4600 DA finishing machine the customer also purchased a fully automatic centrifuge, type Z 1000 for cleaning of the process water. Besides the new finishing system this unit also handles all existing rotary vibrators. With a centrifugal force of up to 2,000 g the centrifuge removes solid particles bigger than 2 µm from the process water. Discharge of the sludge weighing up to 30 kg (66 lbs.) from the rotating drum takes place fully automatically. While in competitive centrifugal systems the peeling knife is constantly rotating with the drum, the Z 1000 is equipped with a stationary peeling knife. During the peeling cycle the knife pneumatically moves to the inner wall of the slowly rotating drum and removes the sludge without placing any additional load on the drum bearings. Upon completion of the peeling cycle the inside of the drum is cleaned by a spray rinse system. This prevents any sludge deposits, which during subsequent peeling cycles might lead to an imbalance causing premat re wear of the drum bearings. Mr. Buzek concludes: “In the past we cleaned our process water chemically or with a semi-automatic centrifuge. This was highly labor intensive and costly. With respect to process water-cleaning Rösler provided us again with the optimum solution. We are certain that with the new equipment we will not only improve the quality of our finishing operation but, at the same time, will become more cost efficient.”

Partner

Foundry Corporate News

Topic Low-pressure diecasting

Topic Pressure Die Casting

Topic Discharging, Decoring, Fettling, Finishing

RÖSLER - Fast and cost effective finishing of aluminum die-castings

Reading time: min

[6]